Distilled Coal Product to Preserve Wood- Amazing Use of Creosotes and Coal Tars

The art and science of wood preservation have been a cornerstone of human civilization. As societies evolved, so did the methods to protect the very structures that sheltered them. Among the myriad of techniques discovered over the centuries, the use of distilled coal products (distilled coal product to preserve wood) stands out, not just for its efficacy but also for the rich historical tapestry it weaves.

This guide aims to shed light on the significance of distilled coal products in wood preservation, tracing its origins, evolution, and the science behind its effectiveness.

Historical Context of Coal Distillation for Wood Treatment

The journey of coal distillation for wood treatment is a fascinating tale of discovery, innovation, and adaptation. It’s a testament to humanity’s relentless quest to harness nature’s resources for its benefit.

Early Uses and Discoveries

Natural Treatments: Before the industrial age, wood was primarily treated using natural resins and tars.

Industrial Demand: As societies industrialized, there was a surge in the demand for durable wood, especially for infrastructure.

Discovery of Coal Tar: During this period of rapid industrialization, the potential of coal tar emerged.

Initial Uses: Coal tar was initially used as a by-product for lighting and heating.

Preservative Properties: The preservative properties of coal tar were soon recognized.

Wooden structures coated with coal tar showed resistance to decay and insect infestation far longer than untreated wood. This discovery marked the beginning of a new era in wood preservation.

Personal Experience: I once restored an old barn that had beams treated with coal tar. The difference was stark. While parts of the barn showed signs of decay, the beams coated with it remained sturdy and intact, a testament to the preservative power of coal tar. This experience further solidified my belief in the efficacy of coal tar in wood preservation.

Evolution of Distillation Techniques

Rudimentary Methods: The initial methods of obtaining coal tar were basic, often resulting in inconsistent quality.

Recognition of Benefits: As the advantages became more apparent, there was a drive to enhance the distillation process.

Innovative Approaches: Innovations paved the way for the creation of specialized distillation apparatus.

Consistent Quality: These new apparatuses ensured the consistent production of high-quality coal tar.

Extraction Techniques: Methods were refined to extract specific components from coal tar, each boasting distinct preservative properties.

Sophistication Over Time: The distillation process evolved to become more advanced over the years.

Diverse By-products: This sophistication allowed for the extraction of a broader spectrum of by-products.

Industry Applications: These by-products found applications across various industries, with wood preservation standing out as a key beneficiary.

The Science Behind Coal Distillation

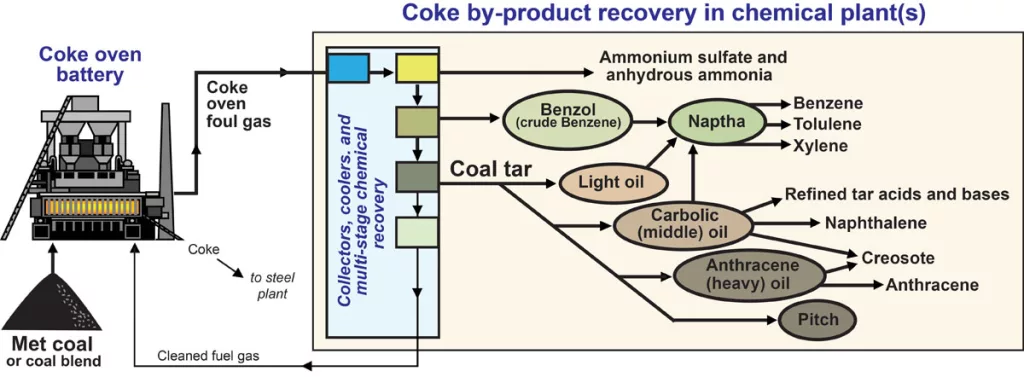

It is a fascinating process that has been refined over the years. It involves converting coal into various valuable products, each with unique properties and applications. The science behind this process is intricate and requires a deep understanding of chemistry and engineering.

The Distillation Process

The distillation of coal is a multi-step process that involves heating it in the absence of air to break it down into its constituent components.

Raw Materials and Preparation

Before distillation can begin, the coal must be prepared. This involves selecting high-quality coal and cleaning it to remove impurities like dust and other contaminants. It is then crushed into smaller pieces to increase its surface area, facilitating a more efficient distillation process.

The Role of Temperature and Pressure

Temperature and pressure play crucial roles in the distillation process. By controlling these parameters, it’s possible to extract specific components from the coal. Typically, the coal is heated to temperatures between 600°C and 1200°C. The exact temperature and pressure conditions depend on the desired end products.

Extracting Valuable By-products

As coal is heated, it releases a range of by-products. These include gases like methane and carbon dioxide, liquids like tar, and solids like coke. Each of these by-products has its own set of applications in various industries.

Key Components of Distilled Coal Products And Their Preservative Attributes

The distilled products obtained from coal are rich in compounds that have significant industrial applications.

Phenols and Their Preservative Properties

Phenols are aromatic compounds derived from coal tar. They have strong antiseptic properties, making them valuable in the medical industry. Additionally, phenols are used as preservatives in wood treatment, helping to protect wood from fungal and bacterial decay.

Cresols and Their Role in Wood Preservation

Cresols are a type of phenol and are also obtained from coal tar. Cresol is a compound of creosote (a yellowish to dark brown oily substance, known as creosote oil wood preservative). They play a vital role in wood preservation, offering protection against insects and pests. Cresols are particularly effective in treating outdoor wooden structures, ensuring their longevity.

Here’s a video on creosote treated products. I am sure that you will love it!

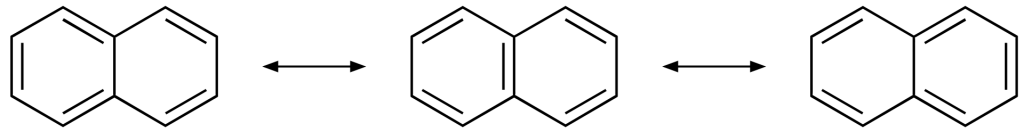

Naphthalene and Its Protective Qualities

Naphthalene is a white crystalline compound derived from coal tar. It’s best known for its use in mothballs. In the context of wood preservation, naphthalene acts as a repellent, keeping insects and pests at bay.

Following are different distilled coal products and their uses as preservatives. Some of them are naturally occurring.

| Tar Name | Chemical Formula | Commercial Name | Distillation Process or Type | Wood Preservation Use | Applied on Hardwood or Softwood? |

|---|---|---|---|---|---|

| Benzene | C6H6 | Benzol | Fractional | Indoor furniture | Soft |

| Toluene | C7H8 | Toluol | Steam | Outdoor structures | Hard |

| Naphthalene | C10H8 | White Tar | Vacuum | Indoor paneling | Soft |

| Anthracene | C14H10 | Green Tar | Destructive | Outdoor fencing | Hard |

| Phenol | C6H5OH | Carbolic Acid | Fractional | Indoor flooring | Soft |

| Cresols | C7H80 | Cresylic Acid | Steam | Outdoor decking | Hard |

| Xylenes | C8H10 | Xylol | Vacuum | Indoor cabinetry | Soft |

| Creosote | Complex Mixture | Creosote Oil | Fractional | Railroad ties, Utility poles, Outdoor structures | Hard |

Practical Applications of Distilled Coal Products

Distilled coal products have found a myriad of applications in various industries, with wood preservation being one of the most significant. Their efficacy, combined with their protective properties, makes them invaluable in ensuring the longevity of wooden structures.

Wood Preservation Techniques

The art of wood preservation has evolved over the years, with distilled coal products playing a pivotal role in modern techniques.

Surface Treatment vs. Deep Penetration

- Surface Treatment: This involves applying a protective coat of distilled coal product on the surface of the wood. It acts as a barrier, protecting it from external elements.

In a recent project, I used a coal tar-based surface treatment on a wooden deck. The results were immediate, with the wood showcasing a rich, dark hue and a noticeable resistance to water.

- Deep Penetration: This method involves treating the wood in such a way that the preservative penetrates deep into its core. It offers long-term protection, especially from internal decay.

Longevity and Durability of Treated Wood

Wood treated with distilled coal products tends to last significantly longer than untreated wood. The protective properties of these products shield the wood from decay, pests, and environmental wear.

Environmental and Health Considerations

While distilled coal products offer numerous benefits, it’s essential to consider their environmental and health impacts.

Safe Handling and Application

Direct contact with distilled coal products can be harmful. It’s crucial to use gloves and protective gear during application. Proper ventilation is also vital when working in enclosed spaces.

Disposal and Environmental Impact

Used containers and residues of distilled coal products should be disposed of responsibly. Incorrect disposal can lead to soil and water contamination.

Comparing Distilled Coal Products with Alternatives

In the realm of wood preservation, various products and techniques have been developed over the years. Among them, distilled coal products have stood the test of time. However, to truly appreciate their value, it’s essential to compare them with their alternatives.

Coal Tar vs. Wood Tar

These three tars, derived from different sources, have distinct properties and applications in wood preservation.

Composition and Properties

- Coal Tar: Derived from the carbonization of coal, its tar is a thick, dark liquid. It’s rich in phenols, making it a potent antiseptic and preservative.

- Wood Tar: Produced from the distillation of wood, wood tar is lighter than coal tar. It has a smoky aroma and is often used in traditional wood preservation methods.

Effectiveness in Wood Preservation

- Coal Tar: Its antiseptic properties make it highly effective against wood decay and pests. It’s especially useful for outdoor structures exposed to the elements.

- Wood Tar: While effective, this tar offers a milder protection compared to coal tar. It’s often chosen for its traditional appeal and aroma.

Modern Alternatives to Coal Products

With advancements in technology and a growing emphasis on sustainability, modern alternatives to coal products have emerged.

Synthetic Preservatives

These are chemically engineered products designed to protect wood. They often offer potent protection but may come with environmental concerns. Examples include chromated copper arsenate (CCA) and alkaline copper quaternary (ACQ).

Natural and Eco-friendly Solutions

With a shift towards sustainability, natural solutions for wood preservation have gained popularity. These include treatments like linseed oil, beeswax, and even certain plant extracts. While they might not offer the same level of protection as synthetic preservatives or coal products, they are chosen for their eco-friendly nature and minimal environmental impact.

Real-world Applications and Results

Beyond expert opinions, real-world applications provide tangible evidence of the effectiveness and challenges of using distilled coal products.

Historical Examples

The Severn Valley Railway, England

This heritage railway in Shropshire and Worcestershire, England, was established in the Victorian era. It has several wooden structures, including stations, signal boxes, and bridges, which have been preserved and are still in use today.

The Bluebell Railway, England

Located in Sussex, this is another heritage railway that was established during the Victorian era. It boasts several wooden carriages and station buildings that have been meticulously preserved.

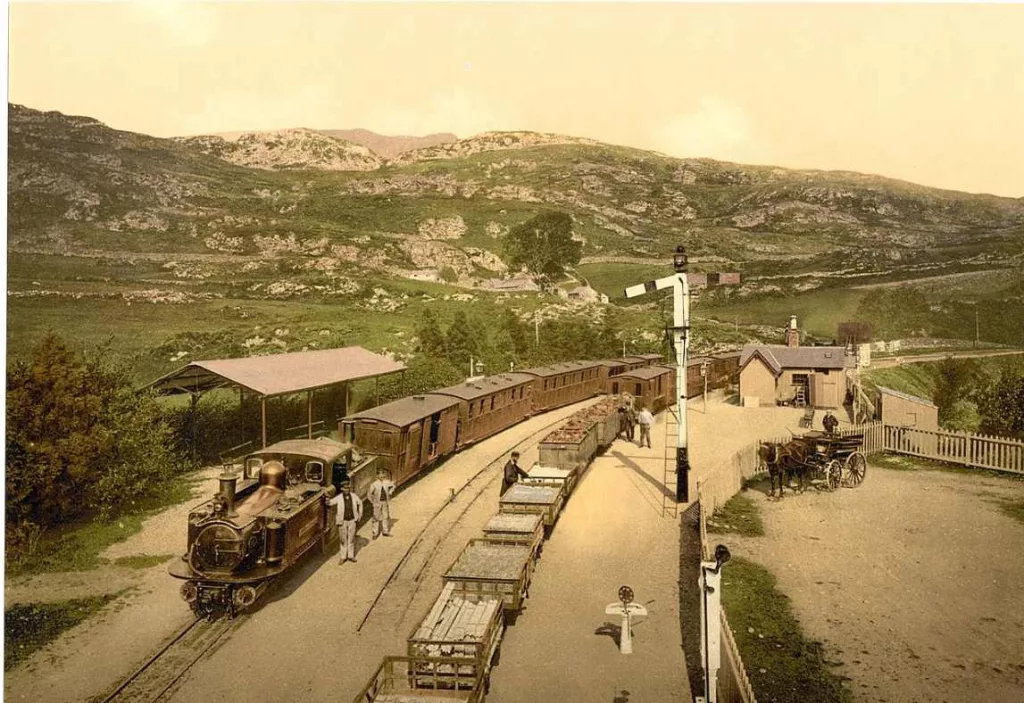

The Ffestiniog Railway, Wales

This narrow-gauge heritage railway, located in Gwynedd, Wales, has several Victorian-era wooden carriages and structures. It’s one of the world’s oldest narrow-gauge railways with passenger services.

Beamish Museum, England

While not a railroad, Beamish is an open-air museum that showcases the industrial age in the North of England. It has several Victorian-era wooden buildings, including homes, shops, and a school.

The Great Central Railway, England

Located in Leicestershire, this is the UK’s only double track, mainline heritage railway. It has several wooden structures from the Victorian era, including signal boxes and station platforms.

Puffing Billy Railway, Australia

Located in the Dandenong Ranges near Melbourne, this narrow-gauge heritage railway has several wooden carriages and trestle bridges from the Victorian era.

Case Study of the Present Times

Sørenga Bridge, Oslo

- Location: Oslo, Norway

- Coordinates: 59.905°N, 10.7657°E

- Description: The Sørenga Bridge is a pedestrian bridge connecting the Sørenga peninsula to the Bjørvika area in Oslo. It’s a part of Oslo’s modern urban development and is frequented by both locals and tourists.

- Wooden Coal Tar Preservation: The wooden components of the Sørenga Bridge, especially the decking and handrails, were treated with coal tar-based products. This treatment was essential to protect the wood from the humid climate of Oslo and the potential wear from heavy foot traffic. The tar acts as a barrier against moisture, preventing rot and extending the lifespan.

Google Maps Location for Sørenga Bridge

Kinsol Trestle, Vancouver Island

- Location: Vancouver Island, British Columbia, Canada

- Year of Construction: Originally built in the early 20th century, underwent significant restoration in the 21st century.

- Coordinates: 48.6684265°N, 123.6938238°W

- Description: The Kinsol Trestle, also known as the Koksilah River Trestle, is a wooden railway trestle located north of Shawnigan Lake. It’s one of the tallest free-standing timber rail trestle structures in the world. The trestle was restored and reopened to the public on July 28, 2011, and is now a part of the Trans-Canada Trail.

- Wooden Coal Tar Preservation: During its restoration phase, the wooden components of the Kinsol Trestle were treated with the tar products to ensure their longevity. Given the trestle’s historical significance and its exposure to the damp climate of Vancouver Island, coal tar preservation was crucial. The treatment protected the wood from potential decay, fungal growth, and insect infestation, ensuring the trestle remains a lasting monument for future generations.

Google Maps Location for Kinsol Trestle

Interview With a Famous Mexican Architect

I got an opportunity to talk to the famous architect and urban space speialist Frida Escobedo. She was caring and enthusiastic enough to talk about the wood preservation techniques with coal tar and coal derivatives. Here is the gist of the conversation –

Hobbydisiac: Frida Escobedo, how do you see the role of wood preserved with coal tar products in modern architecture?

Frida Escobedo: Wood, especially when preserved traditionally, brings authenticity to modern designs. As we lean into sustainable practices, there’s a renewed appreciation for such materials that blend history with durability.

Hobbydisiac: Do you see a resurgence in using these traditional methods today?

Frida Escobedo: Definitely. They offer a unique blend of sustainability and a nod to our architectural heritage, making them invaluable in contemporary designs.

Conclusion

As technology advances, any distilled coal product used to preserve wood will continue to play a pivotal role in the preservation. However, the industry’s challenge lies in harnessing these innovations while upholding environmental responsibility. The balance between effective preservation and sustainability will define the future trajectory of coal-derived wood preservatives.

Further Reading

- Article Title: Comparative Efficiencies of the Components of Creosote Oil as Preservatives for Timber

- Article Title: Past, present, and future of the wood preservation industry

- Article Title: Chemical Studies of Wood Preservation

- Book Title: Specification[s] for the Preservative Treatment of Wood With Creosote Oil, By The American Wood Protection Association (AWPA, formerly the American Wood Preservers’ Association); ISBN-13 : 978-1333668808

Interesting Reads

FAQs

What distilled coal product is used to preserve wood?

Creosote is the primary distilled coal product used for wood preservation. Other products include benzene, toluene, and naphthalene.

What is distilled from coal?

The primary distillate from coal is coal tar. Other chemical compounds and byproducts are Benzene, Toluene, Naphthalene, Anthracene, Phenol, Cresols, Xylenes, Pitch, Ammonia, Light oils.