Janka Hardness Scale for Wood: Superb Guide to Wood Hardness

The measure ‘janka hardness scale for wood’ is crucial for many woodworkers, craftsmen, and industry professionals to make informed decisions on the most suitable wood species for their projects.

Wood is an age-old material used for myriad purposes, from construction and cabinetry to intricate carving and fine furniture. However, not all wood is created equal – some species are harder and more durable than others. This is where the Janka Wood Hardness Scale steps in, offering a standardized measure of the resistance of wood to denting and wear.

Development of Janka Wood Hardness Scale

The Brainchild of Gabriel Janka

The Hardness Test was developed by Austrian-born American wood researcher Gabriel Janka (1864-1932). Janka’s ingenious method allowed for a more systematic approach to understanding relative hardness of wood, a critical factor that influences the wood’s longevity and suitability for various applications [3]. Early in my career as a budding wood specialist, learning about this innovation was akin to finding a compass in the complex world of woodworking. His methodology provided a framework that helped me anticipate the behavior of different wood species under stress, thus significantly informing my material selection process for numerous projects.

Evolution of the Janka Hardness Test

Over the years, the test has undergone refinements, with ASTM D1037 becoming a commonly accepted standard for conducting these tests. This evolution reflects the woodworking industry’s enduring commitment to ensuring accurate and consistent hardness measurements. Throughout my experiences, adapting to the updated standards was essential. The ASTM D1037, for instance, offered a more nuanced understanding, which proved pivotal in a project where we had to select the most suitable hardwood for crafting resilient furniture for a bustling café.

How Hardness is Measured in The Test

The Testing Procedure

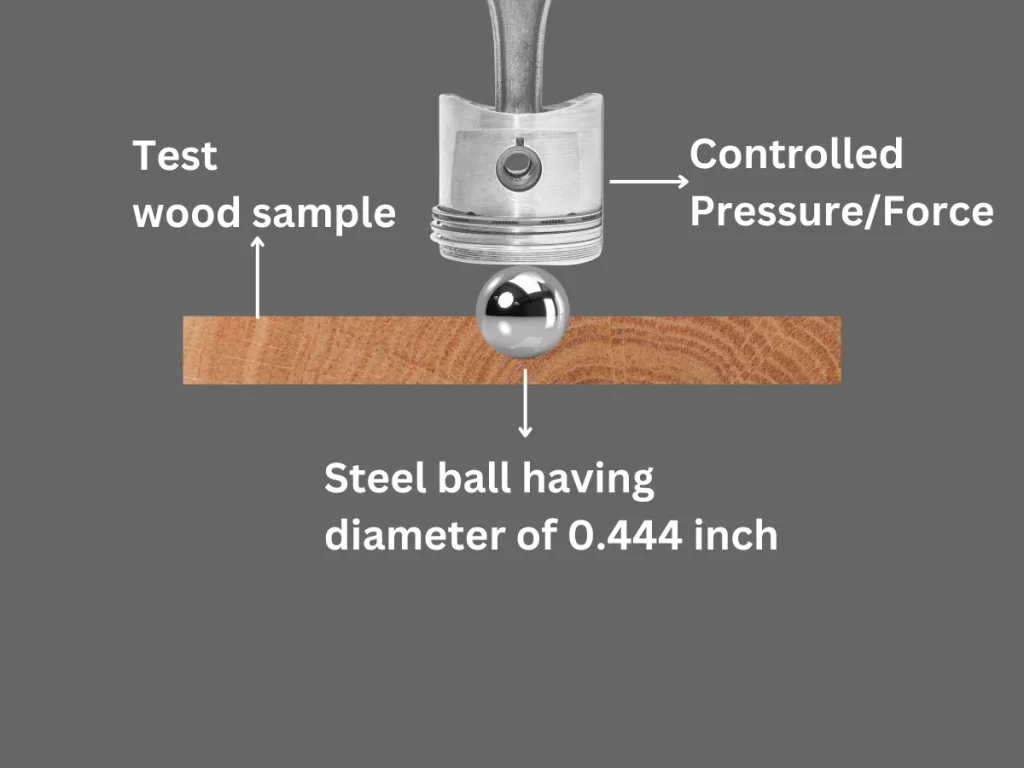

It measures the force required to embed an 11.28-millimeter-diameter (0.444 inches) steel ball halfway into a wood sample. This particular diameter was chosen to produce a circle with an area of 100 square millimeters [2]. These precise measurements ensure the consistency and repeatability of the test across different wood species. In my pursuit to master the essence of wood hardness, I’ve spent countless hours replicating the Janka test in my workshop, fostering a deep appreciation for the meticulous nature of this testing procedure.

Check this video on the scale as well.

Grain Direction and its Impact on Hardness

Wood hardness can vary significantly depending on the direction of the grain. Tests conducted on the surface of a plank, perpendicular to the grain, measure what is known as “side hardness.” Conversely, testing the cut surface of a stump measures “end hardness”. This distinction is critical as it can influence the choice of wood for specific applications.

My encounter with this reality was profound during a commission to restore a century-old farmhouse, where understanding the grain direction proved crucial in choosing the right wood to match the original flooring while ensuring durability.

Standard Testing Conditions

The standard conditions for the Janka test, according to ASTM D143, specify a wood sample with 12% moisture content and clear of knots. These conditions ensure that the measurements are consistent and comparable across different species.

In the university laboratory cum workshop in my undergrad studies, adhering to these standard conditions had been pivotal in ensuring the reliability of the hardness data collected, which in turn, has significantly impacted the quality and durability of the final products crafted.

Variability in Janka Hardness Ratings

Janka numbers are averaged, yet there’s a standard deviation associated with each species. This variability underscores the natural diversity in wood hardness, even within the same species.

During a particular project, I was tasked with crafting custom cabinetry for a vintage-themed diner. The variance in hardness even within the chosen maple wood required precise selection to maintain a consistent finish, showcasing the nuanced reality the Janka hardness scale brings to light.

Regional Measurement Disparities

The results are stated in various units—pounds-force (lbf) in the United States, kilograms-force (kgf) in Sweden, and either in newtons (N) or kilonewtons (kN) in Australia, leading to potential confusion when comparing results across regions.

This came to fore during an international collaborative project where the difference in units led to an initial mismatch in material expectations. However, a swift conversion and explanation of the Janka ratings bridged the understanding gap, ensuring the project proceeded seamlessly.

Applications of Janka rating

Flooring Suitability Assessment

One common use of Janka ratings is in determining the suitability of a particular wood for flooring. The hardness of the wood can significantly impact its wear resistance, and by extension, its longevity as a flooring material.

Early in my woodworking journey, I had the privilege of restoring a historical residence. The task demanded a keen understanding of different wood types to match the existing original floors. Utilizing the Janka hardness ratings, I was able to narrow down the choices, ultimately opting for White Oak, known for its high hardness rating and enduring elegance.

Furniture Manufacturing

- Assessing Wood Suitability: Employing facts to choose appropriate woods for different types of furniture.

- Quality Assurance: Ensuring the durability and longevity of furniture pieces by selecting woods with adequate hardness ratings.

Cabinetry and Millwork

- Material Selection: Utilizing the data to determine the best wood species for cabinets, moldings, and other millwork projects.

- Wear Resistance: Evaluating how well a wood can withstand the daily wear and tear typical in kitchen and bathroom environments.

Woodworking Projects

- Craftsmanship Precision: Leveraging this scale to foresee how different woods will respond to cutting, carving, and other woodworking processes.

- Custom Creations: Tailoring project materials based on Janka ratings to meet the specific needs and expectations of clients or projects.

Outdoor Structures

- Weather Resilience: Selecting woods with higher test values for outdoor structures like decks, patios, and pergolas to endure weather elements.

- Long-term Sustainability: Ensuring the structural integrity of outdoor wooden structures by considering their Janka ratings.

Sporting Goods Manufacturing

- Performance Optimization: Choosing woods with suitable data range for crafting durable and high-performing sporting goods like baseball bats, bows, and croquet mallets.

- Safety Considerations: Utilizing the scale to help in the design of sporting goods that can withstand high-stress impacts without splintering or breaking.

Musical Instrument Crafting

- Tonality and Durability: Selecting the material based on Janka ratings to achieve desired tonal qualities and durability in musical instruments like guitars, violins, and pianos.

- Craftsmanship Longevity: Ensuring the longevity of crafted musical instruments by considering the hardness of the wood in design and construction phases.

Boat Building

- Structural Integrity: Employing the chart to choose woods capable of withstanding the rigors of aquatic environments in boat construction.

- Maintenance Reduction: Selecting harder woods as per the scale to minimize maintenance needs and enhance the lifespan of water vessels.

Following are the the Janka rating values, sorted from highest to lowest, of some woods

| Janka Hardness Value/Scale or Janka Rating for different woods | |||

| Wood Species | Scientific Name | Janka Hardness (lbf) | Janka Hardness (N) ( = lbf X 4.44 N) |

| Quebracho | Schinopsis spp. | 4570 | 20327 |

| Lignum Vitae | Guaiacum officinale or Guaiacum sanctum | 4500 | 20016 |

| Gidgee | Acacia cambagei | 4270 | 18993 |

| Ironwood wattle | Acacia excelsa | 4050 | 18014 |

| Verawood | Bulnesia spp. | 3710 | 16502 |

| Black Ironwood | Krugiodendron ferreum | 3660 | 16280 |

| Cumaru | Dipteryx odorata | 3540 | 15746 |

| Kingwood | Dalbergia cearensis | 3340 | 14856 |

| Desert Ironwood | Olneya tesota | 3260 | 14500 |

| Ebony | Diospyros spp. | 3080 | 13700 |

| Cocobolo | Dalbergia retusa | 2960 | 13166 |

| Bloodwood | Brosimum rubescens | 2900 | 12899 |

| Olive | Olea europaea | 2700 | 12010 |

| Jatoba | Hymenaea courbaril | 2690 | 11965 |

| Osage Orange | Maclura pomifera | 2620 | 11654 |

| Lebombo Ironwood | Androstachys johnsonii | 2610 | 11609 |

| Greenheart | Chlorocardium rodiei | 2530 | 11253 |

| Purpleheart | Peltogyne spp. | 2520 | 11209 |

| Purple Heart | Peltogyne spp. | 2520 | 11209 |

| Brazilian Cherry | Hymenaea courbaril | 2350 | 10453 |

| Persimmon | Diospyros virginiana | 2300 | 10230 |

| Karri | Eucalyptus diversicolor | 2030 | 9029 |

| Ziricote | Cordia dodecandra | 1970 | 8763 |

| Bolivian Rosewood | Machaerium scleroxylon | 1960 | 8718 |

| Wenge | Millettia laurentii | 1930 | 8585 |

| Jarrah | Eucalyptus marginata | 1860 | 8273 |

| Hophornbeam | Ostrya virginiana | 1860 | 8273 |

| Zebrawood | Microberlinia brazzavillensis | 1830 | 8140 |

| Hickory | Carya spp. | 1820 | 8095 |

| Pecan | Carya illinoinensis | 1820 | 8095 |

| Yellowheart | Euxylophora paraensis | 1790 | 7962 |

| African Padauk | Pterocarpus soyauxii | 1710 | 7606 |

| Black Locust | Robinia pseudoacacia | 1700 | 7562 |

| Garapa | Apuleia leiocarpa | 1650 | 7339 |

| Honey Locust | Gleditsia triacanthos | 1580 | 7028 |

| Yew | Taxus baccata | 1520 | 6761 |

| Hard Maple | Acer saccharum | 1450 | 6450 |

| European Beech | Fagus sylvatica | 1450 | 6450 |

| Hard Maple | Acer saccharum | 1450 | 6450 |

| Bamboo | Bambuseae tribe (various genera) | 1380 | 6138 |

| Sapele | Entandrophragma cylindricum | 1360 | 6049 |

| White Oak | Quercus alba | 1360 | 6049 |

| Yellow Birch | Betula alleghaniensis | 1260 | 5604 |

| Red Oak | Quercus rubra | 1220 | 5427 |

| Iroko | Milicia excelsa | 1190 | 5293 |

| Koa | Acacia koa | 1170 | 5204 |

| European Oak (English Oak) | Quercus robur | 1120 | 4982 |

| Siberian Larch | Larix sibirica | 1100 | 4893 |

| Teak | Tectona grandis | 1070 | 4759 |

| Black Walnut | Juglans nigra | 1010 | 4492 |

| Walnut | Juglans spp. | 1010 | 4492 |

| Rubberwood | Hevea brasiliensis | 960 | 4270 |

| Black Cherry | Prunus serotina | 950 | 4226 |

| Soft Maple | Acer rubrum or Acer saccharinum | 950 | 4226 |

| Hackberry | Celtis occidentalis | 880 | 3914 |

| Longleaf Pine | Pinus palustris | 870 | 3870 |

| Southern Yellow Pine | Pinus spp. (various species) | 870 | 3870 |

| Lacewood | Cardwellia sublimis | 840 | 3736 |

| Elm | Ulmus spp. | 830 | 3692 |

| American Elm | Ulmus americana | 830 | 3692 |

| Elm | Ulmus spp. | 830 | 3692 |

| Mahogany | Swietenia spp. | 800 | 3558 |

| European Larch | Larix decidua | 740 | 3292 |

| Radiata Pine | Pinus radiata | 710 | 3158 |

| Silver Maple | Acer saccharinum | 700 | 3114 |

| Western Juniper | Juniperus occidentalis | 680 | 3025 |

| Sweet Chestnut | Castanea sativa | 680 | 3025 |

| Douglas Fir | Pseudotsuga menziesii | 620 | 2758 |

| Alder | Alnus spp. | 590 | 2624 |

| Yellow Poplar | Liriodendron tulipifera | 540 | 2402 |

| Chestnut | Castanea spp. | 540 | 2402 |

| Scots Pine | Pinus sylvestris | 540 | 2402 |

| Poplar | Populus spp. | 540 | 2402 |

| White Spruce | Picea glauca | 510 | 2268 |

| Hemlock | Tsuga spp. | 500 | 2224 |

| Basswood | Tilia americana | 410 | 1824 |

| Okoume | Aucoumea klaineana | 400 | 1779 |

| Eastern White Pine | Pinus strobus | 380 | 1690 |

| Quaking Aspen | Populus tremuloides | 350 | 1557 |

| Red Cedar | Thuja plicata | 350 | 1557 |

| Western Red Cedar | Thuja plicata | 350 | 1557 |

| Paulownia | Paulownia tomentosa | 300 | 1334 |

| Balsa | Ochroma pyramidale | 100 | 445 |

Representation and Interpretation of Janka Hardness Ratings

Tabulation and Averaging of Test Results

The test results are usually tabulated following ASTM D 1037-12 testing methods, providing a comparative platform for different wood species. However, no testing was done on actual flooring, indicating a potential area for further research and analysis3. The disparity between lab tests and real-world conditions often crossed my mind, especially when consulting on flooring choices for high-traffic areas. The theoretical numbers sometimes required an adjustment based on the actual conditions, highlighting a realm ripe for further exploration and understanding.

Discrepancies and Limitations

The absence of testing on actual flooring materials presents a limitation in the real-world applicability of the Janka ratings. Despite this, the test remains a cornerstone in the woodworking and flooring industries. The lore of the Janka Hardness scale is deeply embedded in every wood specialist’s lexicon, mine included. Over the years, these ratings have provided a reliable roadmap guiding countless projects towards a blend of aesthetic charm and structural longevity, albeit with a sprinkle of intuitive adjustments to match the ever-evolving real-world scenarios.

Alternative Hardness Test Methods

Brinell Test

- Measures the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece.

- Commonly used for metals but can be applied to hardened wood as well.

Rockwell Test

- Measures the depth of penetration of an indenter under a large load compared to the penetration made by a preload.

- Useful for determining hardness of various materials including wood, although less common.

Monnin Test

- Specifically designed for wood and wood-based materials.

- Measures the resistance of wood to indentation, similar to the Janka and Brinell tests.

Knoop and Vickers Microhardness Tests

These are micro-indentation tests often used for coatings on brittle or very hard materials, but they can be adapted for high-density wood species. It aims to solve the brittleness issues of the material inside.

Pilodyn Test

- A portable device used to measure the penetration depth of a pin shot into the wood surface under defined conditions.

- Often used in forestry to estimate wood density and thus, indirectly, hardness my measuring the material’s decay or strength loss.

Instrumented Indentation Testing (IIT)

- Measures hardness and other material properties using a sharp indenter tip, often on a microscopic scale.

- While more commonly used in metals and ceramics, it can be adapted for wood materials, particularly for small-scale or microhardness testing.

Shore D Hardness Test

- Though typically used for plastics, it can be adapted to measure hardness in very hard woods.

- Measures the depth of indentation under a standardized spring force.

Conclusion

The Janka Hardness Scale for Wood serves as a vital tool in the hands of professionals and enthusiasts alike, aiding in the choice of the right wood for the right job. While it comes with its set of limitations, its significance in the realm of woodworking is undeniably profound.

FAQs

How is the Janka hardness test conducted?

The Janka hardness test measures the force needed to push a steel ball with a diameter of 0.444 inches into a piece of wood. The test measures the force required to embed the ball into the wood to half its diameter and produces a measurement in pounds-force (lbf) or newtons.

What does the Janka hardness rating measure?

The Janka hardness rating measures the force required to embed a steel ball into the wood. This measurement determines the wood’s relative hardness and durability. A higher Janka hardness rating indicates a harder wood that is more resistant to denting and wear.

What are some examples of wood species with high Janka hardness ratings?

Some examples of wood species with high Janka hardness ratings include Black Ironwood (Krugiodendron ferreum) – 3660 lbf, Cumaru (Dipteryx odorata)- 3540 lbf, Gidgee (Acacia cambagei) – 4270 lbf. These woods are known for their exceptional durability and are often used in applications where hardness is critical, such as flooring or furniture construction for outdoor uses.

How does the Janka hardness scale impact the overall durability of wood?

A higher Janka hardness rating indicates greater resistance to dents, scratches, and wear. Therefore, wood species with higher hardness ratings tend to be more durable and suitable for high-traffic areas or environments prone to impact and wear.

Interesting Reads

References

- ASTM D143 – 14 Standard Test Methods for Small Clear Specimens of Timber

- Janka Hardness (Wikiepedia)

- M. Lewin, et al, Wood Structure and Composition, ISBN 082478233X

- United States Department of Agriculture, Wood Handbook – Wood as an Engineering Material, ISBN-13. 978-0898750829

- Pierre Home Douglas, John Arno, et al., The Art of Woodworking Encyclopedia of wood-Time-Life Books (1993), ISBN-13 : 978-0809499168