Comprehensive Guide to Pressure Treated Wood Preservatives: Ensuring Longevity and Safety

The world of wood preservation is vast and intricate. With the increasing demand for durable outdoor wooden structures, understanding the nuances of pressure treated wood and its preservatives becomes paramount. This guide delves deep into the realm of pressure preservative treated wood, offering insights that are both scientifically accurate and easy for the everyday homeowner to grasp.

Understanding Pressure Treated Wood Preservatives

Pressure treated wood has revolutionized the construction and DIY landscape.

pressure treated wood, with its preservatives, offers a robust solution for those looking to embark on outdoor projects. Its resilience against natural adversaries ensures that structures stand the test of time, providing both beauty and functionality.

But what exactly is it, and why has it become such a staple in modern construction?

What is Pressure Treated Wood?

Pressure treated wood is lumber that has undergone a specialized process to infuse it with preservative chemicals.

- The treatment process uses a pressurized holding tank. It is a vacuum tank. And the preservative enters into the wood fibers due to the negative pressure created in tank by strong vacuum pumps.

- Preservative chemicals flood the chamber from a chemical containing tank.

- Once the chamber is filled, hydraulic or mechanical pressure is applied. This forces the preservative deep into the wood fibers, ensuring thorough saturation. Chemicals are forced deep into the wood fibers during this process.

- The main objective is to protect wood from decay, fungi, and wood-eating insects.

- Unlike surface treatments, pressure treating offers deeper penetration of chemicals.

- This ensures long-lasting protection against external threats.

- The treated wood here is ideal for outdoor use and is called pressure treated wood.

- It’s especially recommended for wood in contact with the ground due to heightened risks of decay and insect damage.

Benefits

- Durability: One of the most significant advantages of pressure treated wood is its enhanced durability. The infused chemicals protect the wood from rot, decay, and insect damage, ensuring a longer lifespan compared to untreated wood.

- Cost-Effective: While the initial cost might be higher than untreated wood, the long-term savings are substantial. Given its durability, pressure treated wood requires less maintenance and replacement over time.

- Versatility: Suitable for a variety of outdoor projects, from decks and fences to garden beds and retaining walls. Its resistance to environmental factors makes it a top choice for structures exposed to the elements.

- Safety: Modern pressure treated wood uses chemicals that are less harmful to the environment and humans than older treatments. This shift ensures that homeowners can enjoy the benefits of preserved wood without significant health concerns.

Innovations in Wood Preservation Technology

- The last decade has witnessed significant strides in wood preservation technology. Nanotechnology, for instance, is being explored to create preservatives that offer enhanced protection at the molecular level. Here’s a research on nanotechnology application on wood pressure treatment.

- Additionally, research is underway to develop non-toxic preservatives derived from natural sources, ensuring safety without compromising on efficacy. Here is a research paper on this: “Non–toxic albumin and soja protein borates as ground-contact wood preservatives” by M. -F. Thevenon, A. Pizzi & J. -P. Haluk

The Science Behind Wood Preservatives

Wood, in its natural state, is susceptible to various external factors like moisture, fungi, and insects. The science of wood preservation delves into understanding these vulnerabilities and devising methods to counteract them.

How They Enhance Durability

Wood preservatives play a pivotal role in enhancing the natural lifespan of wood. By creating a protective barrier against external threats, these chemicals ensure that wood remains robust and intact for years. The preservatives penetrate the wood fibers, making them resistant to fungal decay, rot, and insect infestation. This deep penetration ensures that even if the wood’s surface is damaged or worn out, the inner layers remain protected.

The Role of Chemicals

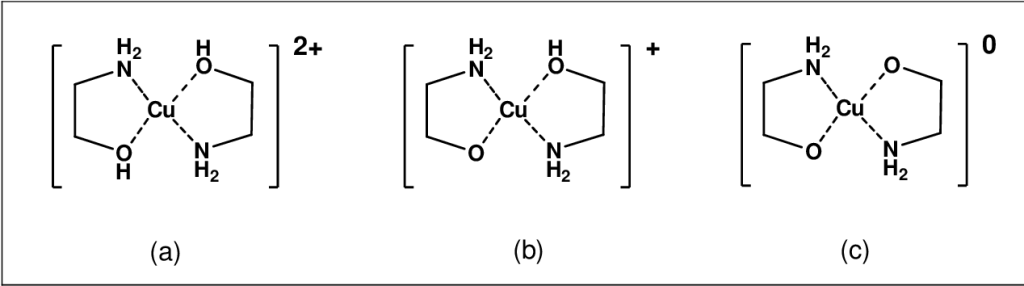

Chemicals are the unsung heroes in the world of wood preservation. They perform the crucial task of safeguarding the wood from biological threats. Some common chemicals used in the preservation process include:

- Alkaline Copper Quaternary (ACQ): A water-based wood preservative that protects against rot, decay, and termite damage.

- Chromated Copper Arsenate (CCA): Historically used for its effectiveness against wood pests, but its use has decreased due to environmental concerns.

The choice of chemical depends on the intended use of the wood, the desired longevity, and environmental considerations.

Environmental and Health Implications

While wood preservatives are essential for durability, it’s crucial to understand their environmental and health implications. Some older preservatives, like CCA, raised concerns due to their arsenic content. Modern preservatives aim to be less toxic while retaining their protective qualities. Proper handling, application, and disposal of treated wood can mitigate potential risks, ensuring safety for both the environment and individuals.

Types of Wood Preservatives for Pressure Treatment

With the evolution of science and technology, various wood preservatives have been developed to cater to different needs and environmental considerations.

Copper Naphthenate-Based

Copper naphthenate is an oil-based preservative known for its effectiveness against fungi and insects. Its greenish hue provides a visual indication of its application. Being oil-based, it offers the added advantage of repelling water, further enhancing wood’s resistance to moisture.

Borate-Based

Borates are water-soluble salts that protect wood from fungi and insects. They are especially favored for indoor applications due to their low toxicity. However, since they are water-soluble, they are not suitable for wood in direct contact with the ground or exposed to frequent moisture.

Alternative and Eco-Friendly Ones

With growing environmental awareness, there’s a push towards eco-friendly wood preservatives. These alternatives, like bio-based treatments, aim to offer protection without the adverse environmental effects associated with traditional chemicals. Research is ongoing to make these alternatives as effective as their chemical counterparts.

Micronized Copper

This is a process where copper particles are micronized or mechanically ground to submicron size. These particles are then suspended in a liquid, allowing the wood to be treated without the use of solvents. Micronized copper treatments, such as Micronized Copper Azole (MCA), are considered more eco-friendly than traditional solvent-based treatments.

Bio-Based Treatments

Research is ongoing to develop wood preservatives derived from natural sources, such as plant extracts and essential oils. These treatments aim to offer protection using renewable resources and are biodegradable.

You can have a read to learn the idea.

“Bio-based wood preservatives: Their efficiency, leaching and ecotoxicity compared to a commercial wood preservative“, Aitor Barbero-López, Jarkko Akkanen, Reijo Lappalainen, Sirpa Peräniemi, Antti Haapala

Bio-Based Chemicals Used for Wood Preservation here:

- Pyrolysis Distillates of Tree Bark: These are by-products obtained from the thermal decomposition of tree bark in the absence of oxygen. The distillates contain various organic compounds that can act as wood preservatives.

- Organic Acids Found in Distillates: The article mentions the use of organic acids that are present in the pyrolysis distillates. These acids can have antifungal properties, making them suitable for wood preservation.

- Colatan GT10 Tannin Extract: Tannins are polyphenolic compounds found in various plants. The Colatan GT10 extract, derived from tannins, showed promising results in wood preservation, performing as well as commercial wood preservatives in some tests.

- Log Soaking Liquid: This is a residue obtained from the hardwood veneer process. The article suggests that this liquid was tested for its potential use in wood preservation.

These bio-based chemicals showed much less eco-toxicity compared to commercially available preservatives.

The Community Garden in My Locality

A community garden near my location uses eco-friendly preservatives for their raised beds. Not only have they withstood the test of time, but they’ve also ensured that the produce remains uncontaminated and organic.

Silicate-Based Treatments

Potassium silicate, for instance, can be used to treat wood, making it resistant to decay. When the silicate reacts with carbon dioxide in the atmosphere, it forms a hard, glass-like layer that protects the wood.

Application and Maintenance of Pressure Treated Wood

The longevity and durability of pressure treated wood are not solely dependent on the preservatives used. Proper application and maintenance play a pivotal role in ensuring that the wood remains in optimal condition for years to come.

Proper Application Techniques

The effectiveness of a wood preservative is directly linked to its proper application. Here are some key techniques to ensure optimal protection:

- Even Coating: Ensure that the preservative is applied uniformly across the wood surface. This prevents areas of vulnerability where decay or pests might gain a foothold. You got to keep minor gaps between pieces so that liquid can pass through.

- Deep Penetration: Especially for oil-based preservatives, allowing the chemical to penetrate deep into the wood ensures lasting protection. Small incisions on the plank surfaces are put to let the chemicals enter deeper into the wood.

- Drying Time: After application, give the wood ample time to dry. This ensures that the chemicals are firmly set within the wood fibers.

Field Treating: Ensuring Complete Protection

Field treating refers to the application of preservatives to cuts or holes made post-treatment. This is crucial as untreated or exposed sections can become weak points:

- Immediate Treatment: Treat cuts or holes as soon as they’re made to prevent exposure.

- Use Compatible Preservatives: Ensure that the preservative used for field treating is compatible with the original treatment to ensure uniform protection.

Maintenance Tips

Even with the best preservatives, maintenance is key:

- Regular Inspections: Periodically check for signs of wear, decay, or insect activity.

- Reapplication: Over time, the effectiveness of preservatives can diminish. Consider reapplying every few years, especially in high-exposure areas.

- Clean and Dry: Keep the wood clean and ensure proper drainage to prevent water accumulation.

Addressing Common Myths and Misconceptions

With any widely used product, myths and misconceptions are bound to arise. Let’s debunk some common ones related to pressure treated wood.

Debunking Myths

Historically, Chromated Copper Arsenate (CCA) was a popular wood preservative. Concerns arose due to its arsenic content:

- Fact Check: Modern pressure treated wood rarely uses CCA for residential purposes. Alternatives like ACQ provide protection without the associated risks of arsenic.

Impact on the Environment

There’s a misconception that pressure treated wood is inherently bad for the environment:

- Reality: When sourced responsibly and treated with eco-friendly preservatives, pressure treated wood can be a sustainable choice. Proper disposal and recycling further mitigate environmental impact.

Safety Precautions and Best Practices

Safety first! Here are some guidelines:

- Handling: Wear gloves when handling freshly treated wood to prevent skin contact with preservatives.

- Disposal: Don’t burn pressure treated wood. Dispose of it as per local regulations to prevent chemical release.

- Use in Gardens: Be cautious when using pressure treated wood in vegetable gardens. Consider a barrier between the wood and soil to prevent chemical leaching.

Expert Insights

Working with this type of wood preservatives requires not just theoretical knowledge but also practical insights from those who’ve been in the trenches – the experts.

We sat down with Carlos Fernandez, the ex-sales manager at Indoor Lumber Yard, Minnesota, to gather firsthand knowledge.

He said, “Customers today are more informed and demand quality. They understand that not all treated wood is the same and are willing to invest in premium products for longevity.”

What Homeowners and DIYers Need to Know

For homeowners and DIY enthusiasts, understanding the intricacies of pressure treated wood can be the difference between a project that lasts a season and one that lasts a lifetime.

Choosing the Right Preservative

- Understand the Environment: For damp environments, opt for preservatives that offer robust protection against moisture and fungi.

- Consider the Project: A child’s playset might require different preservatives than a garden shed. Always consider the end use.

Cost-Effective Solutions for Home Use

- Bulk Purchases: If you have a large project, consider buying in bulk for discounts.

- Recycled or Reclaimed Wood: Responsibly sourced reclaimed wood can be both eco-friendly and cost-effective. Just ensure it’s properly treated before use.

Ensuring Safety and Longevity in Outdoor Settings

- Regular Maintenance: Periodic checks and touch-ups can extend the life of your wood structures.

- Safety Gear: When working with treated wood, always use gloves and safety goggles. If cutting or sanding, use a mask to avoid inhaling dust.

Conclusion

As we look forward, this wood preservative area is undergoing transformative changes, driven by technological advancements and a global push towards sustainability. From sourcing wood responsibly to developing biodegradable preservatives, the focus is on minimizing environmental impact.

More Reads on Preservation

Additional Resources and References

For those keen on diving deeper into the world of pressure treated wood and its preservatives, here are some curated resources and references.

- “Future Prospects of Wood Preservation with Nanotechnology” by Hamid R Taghiyari

- Application of nanotechnology in wood preservation by Akhtari, M. ; Arefkhani, M., it is a Conference paper, (41st Annual Meeting of the International Research Group on Wood Protection, Biarritz, France, 9-13 May 2010 ) 2010 pp.IRG-WP 10-30542, Conference Title : 41st Annual Meeting of the International Research Group on Wood Protection, Biarritz, France, 9-13 May 2010.

- “Treatability of wood for pressure treatment processes: a literature review“

- “Manual on Preservative Treatment of Wood by Pressure” by James Donald Maclean – August 24, 2018; ISBN-13 : 978-1527874459

FAQs

Does pressure treated wood need preservative?

No, pressure treated wood already has preservatives infused into it to protect against decay and pests.

Is pressure treated wood the same as preservative treated wood?

Yes, pressure treated wood is a type of preservative treated wood where chemicals are infused into the wood under pressure.

What is the best preservative for pressure treated wood?

The best preservative depends on the intended use, but common choices include Alkaline Copper Quaternary (ACQ) and Copper Azole (CuAz).

Can you preserve pressure treated wood?

Yes, while pressure treated wood is already preserved, you can apply additional sealants or stains to enhance its appearance and longevity.