Mastering Wood Joinery: Exploring 16 Essential Types of Woodworking joints

Wood joinery is an essential aspect of woodworking, involving the art of connecting two pieces of wood to form a strong and seamless bond. Whether you are a novice woodworker or a seasoned craftsman, understanding the various types of wood joints and their applications is crucial for creating durable and visually appealing woodworking projects.

These aren’t just the points where two pieces of wood meet; they’re the heart of craftsmanship, holding our creations together. Whether you’re crafting a simple shelf or an heirloom cabinet, understanding these joints is crucial. They’re not just about utility; they’re about design, strength, and the beauty of woodworking.

What Are Wood Joints?

Understanding the Basics of Wood Joints

Wood joints refer to the method used to join two wood pieces together. They play a crucial role in determining the strength, stability, and aesthetic appeal of the final woodworking project. Whether it’s cabinets, drawers, or frames, the type of joint used significantly impacts the overall quality and durability of the structure.

The Importance of Wood Joints in Woodworking

Woodworking joints are essential as they provide structural integrity and enhance the overall craftsmanship of the project. The choice of joint can determine how long a piece of furniture will last, making it a fundamental consideration for woodworkers aiming for longevity and quality in their creations.

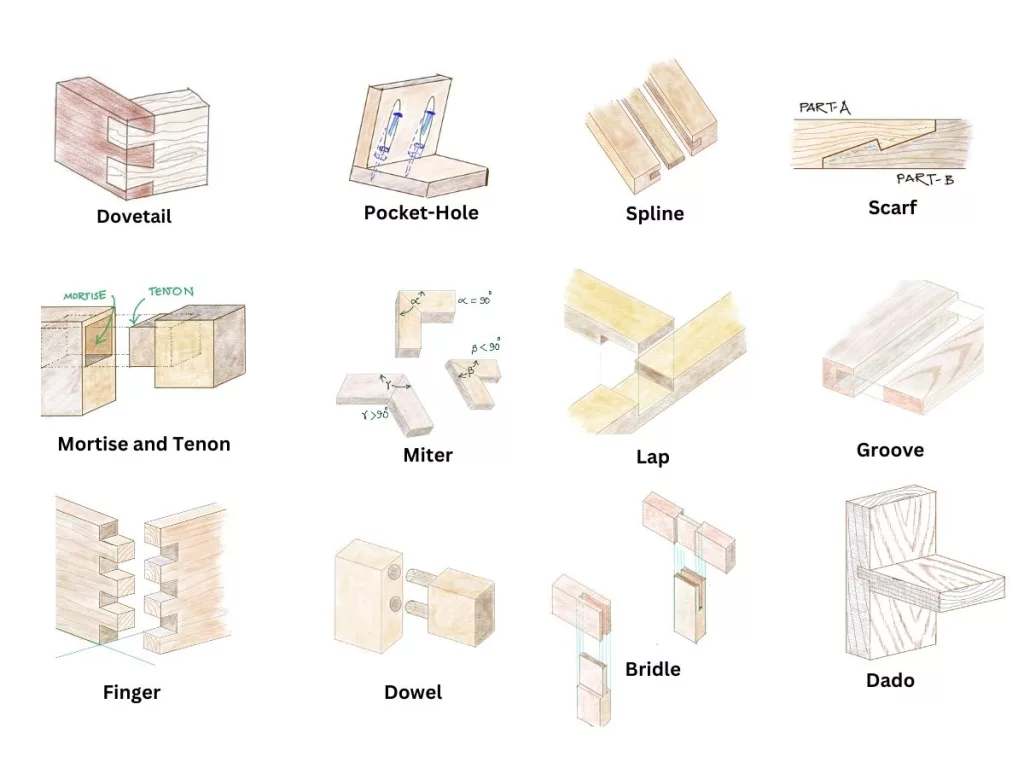

Types of Woodworking joints

Each type of joint offers different strengths and weaknesses. While some joints are suitable for specific applications, others may be more versatile and widely used in various woodworking projects. Understanding and comparing the types of joint woodwork can help woodworkers make informed decisions when selecting the most suitable joint for their projects.

wood joining techniques can certainly be grouped based on various factors such as their structural characteristics, the complexity of execution, the tools required, or their common applications. Here are some common groupings:

- Strength-Based Grouping:

- Strong Joints: Mortise and Tenon, Dovetail, Finger (Box) Joints.

- Moderate Strength Joints: Biscuit, Dowel, Rabbet, Lap Joints.

- Light-Duty Joints: Butt, Miter (when not reinforced).

- Complexity and Skill Level:

- Advanced Joints: Dovetail, Mortise and Tenon, Complex Lap Joints.

- Intermediate Joints: Biscuit, Dowel, Rabbet, Basic Lap Joints.

- Beginner Joints: Butt, Miter, Simple Lap Joints.

- Tool Requirement Grouping:

- Hand Tool Joints: Traditional Dovetail, Mortise and Tenon.

- Power Tool Joints: Biscuit, Dowel, Pocket-Hole.

- Basic Tool Joints: Butt, Miter, Simple Lap Joints.

- Application-Based Grouping:

- Furniture Making: Mortise and Tenon, Dovetail, Finger Joints.

- Cabinetry and Shelving: Biscuit, Dowel, Rabbet, Dado Joints.

- Decorative or Light Use: Miter, Butt, Simple Lap Joints.

- Aesthetic-Based Grouping:

- Visible and Decorative Joints: Dovetail, Exposed Lap Joints.

- Concealed or Subtle Joints: Biscuit, Dowel, Mortise and Tenon.

- Simple or Barely Visible Joints: Butt, Miter, Pocket-Hole.

- Historical/Traditional vs. Modern Techniques:

- Traditional Joints: Dovetail, Mortise and Tenon, Hand-Cut Lap Joints.

- Modern Joints: Biscuit, Pocket-Hole, Machine-Cut Lap and Dowel Joints.

Common Wood Joints

When it comes to furniture making, certain wood joints are commonly used due to their reliability and structural integrity. From dovetail joints in drawers to mortise and tenon joints in frames, these joints contribute to the longevity and stability of the furniture piece.

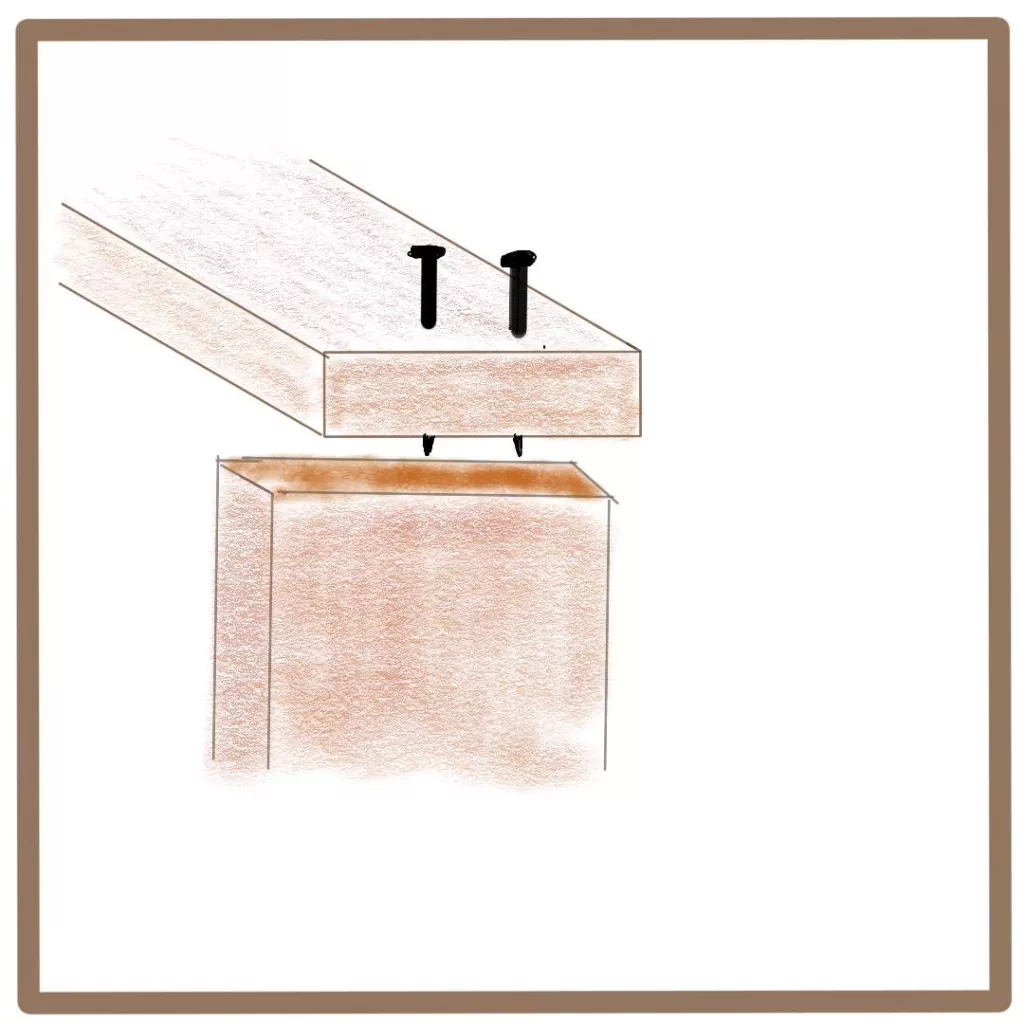

Butt Joint

The Butt Joint is a fundamental and straightforward woodworking joint where two pieces of material are joined at their ends. It is commonly used for its simplicity and ease of construction, but typically requires additional reinforcement due to its inherently low strength.

- Complexity: Simple

- Strength: Low

- Skill Level Required: Beginner

- Tools Required: Basic (hammer, nails/screws, saw)

- Aesthetic Appeal: Low; often hidden in finished work

- Common Uses: Basic framing, cabinetry, and general construction

- Load Bearing Capacity: Low; requires reinforcement for strength

- Time to Create: Quick

- Material Suitability: Versatile (wood, metal, plastic)

- Glue Surface Area: Low; end grain to face or edge grain

- Fastening Method: Glue, nails, screws

- Durability: Low to moderate; depends on reinforcement

- Special Considerations: Often needs additional support (dowels, biscuits, brackets) for stability and strength.

Dovetail Joint

The Dovetail Joint is a strong and visually appealing woodworking joint, characterized by interlocking wedge-shaped cuts. It’s highly regarded for its resistance to being pulled apart and is often used in fine woodworking for both its strength and decorative appeal.

- Complexity: Complex

- Strength: High

- Skill Level Required: Advanced

- Tools Required: Specialized (dovetail saw, chisels)

- Aesthetic Appeal: High; often featured for its attractive pattern

- Common Uses: Fine cabinetry, box construction, drawer making

- Load Bearing Capacity: High; excellent for tension and compression

- Time to Create: Time-consuming

- Material Suitability: Primarily wood

- Glue Surface Area: High; interlocking design increases the area

- Fastening Method: Primarily glue; mechanical fasteners rarely needed

- Durability: High; the joint’s design ensures long-lasting strength

- Special Considerations: Requires precise cutting and fitting; often used where a strong, decorative joint is desired.

Biscuit Joint

The Biscuit Joint is a modern woodworking method that involves inserting a ‘biscuit’—a small, oval-shaped piece of compressed wood—to align and strengthen the connection between two pieces. It’s popular for its simplicity and effectiveness in creating strong, aligned joints in panel glue-ups and cabinetry.

- Complexity: Simple

- Strength: Moderate

- Skill Level Required: Beginner to Intermediate

- Tools Required: Specialized (biscuit joiner or plate joiner)

- Aesthetic Appeal: Moderate; usually hidden within the work

- Common Uses: Panel glue-ups, cabinetry, furniture making

- Load Bearing Capacity: Moderate; provides good reinforcement

- Time to Create: Quick

- Material Suitability: Wood and some composites

- Glue Surface Area: Moderate; increased by the surface area of the biscuit

- Fastening Method: Glue and biscuits

- Durability: Moderate; reliable for many types of joinery

- Special Considerations: Ideal for aligning edges and strengthening joints, especially in sheet goods and board materials.

Spline Joint

The Spline Joint is a refined woodworking technique where a thin strip of wood (spline) is inserted into matching grooves cut into two joining pieces. This joint is appreciated for its ability to reinforce and align edges, commonly used in mitered corners and panel glue-ups.

- Complexity: Moderate

- Strength: High

- Skill Level Required: Intermediate

- Tools Required: Router or table saw for cutting grooves, spline material

- Aesthetic Appeal: Moderate to High; can be decorative if the spline is visible

- Common Uses: Picture frames, box lids, panel joining

- Load Bearing Capacity: Moderate to High; adds significant strength to mitered corners and panel joints

- Time to Create: Moderate

- Material Suitability: Primarily wood, including contrasting woods for decorative splines

- Glue Surface Area: High; the spline increases the glued surface area

- Fastening Method: Glue, with the spline serving as a mechanical reinforcement

- Durability: High; the spline adds stability and strength to the joint

- Special Considerations: Ideal for reinforcing miter joints or aligning boards; the choice of spline material can add a decorative element to the joint.

Biscuit Joint vs Spline Joint

Both biscuit and spline joints are used to align and strengthen joints in woodworking, utilizing inserted pieces (biscuits or splines) in specially cut slots to enhance the connection between two pieces of wood. Nevertheless, these joints are very dissimilar in forms and functions.

| Feature | Biscuit Joint | Spline Joint |

|---|---|---|

| Construction | Uses oval-shaped biscuits inserted into matching slots | Uses a strip of wood (spline) inserted into grooves |

| Tools Required | Biscuit joiner (or plate joiner) | Router or table saw |

| Common Applications | Panel glue-ups, cabinetry, furniture making | Mitered corners, box construction, panel joining |

| Strength | Moderate, mainly for alignment and reinforcement | Higher, especially in mitered applications |

| Aesthetic | Hidden within the work, not visible in final product | Can be decorative if visible, using contrasting woods |

| Ease of Use | Relatively easy, suitable for beginners | Requires more precision, suitable for intermediate users |

| Alignment Flexibility | Allows some flexibility due to biscuit shape | Less flexible; requires precise cutting |

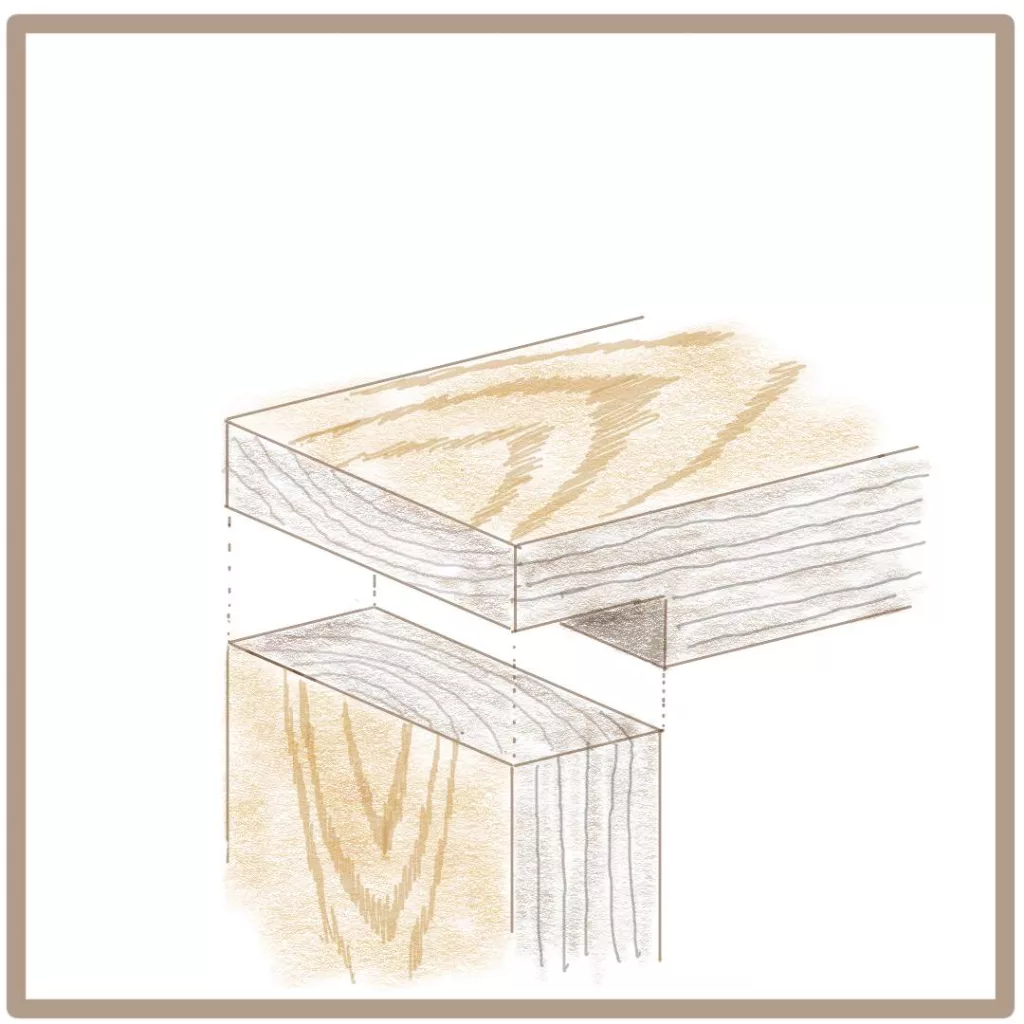

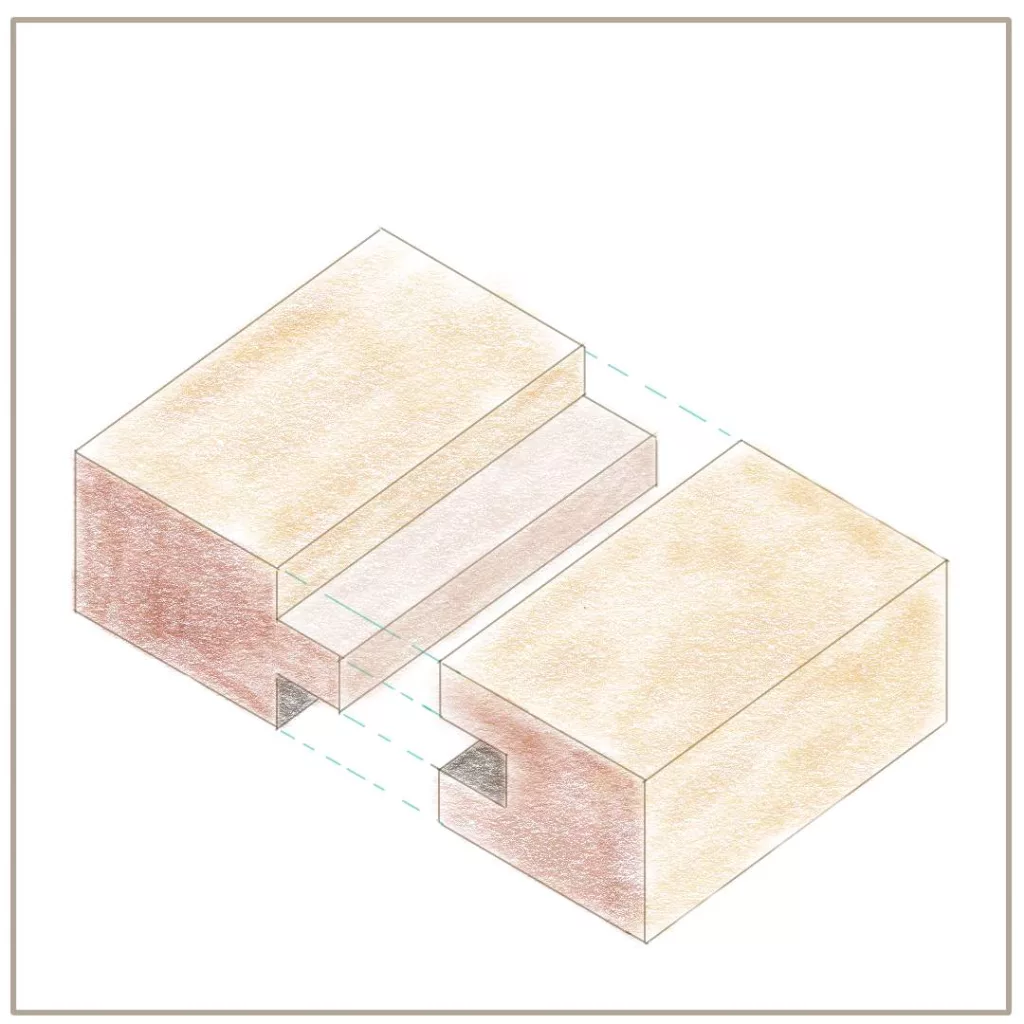

Dado Joint

The Dado Joint is a traditional woodworking technique where a slot or trench is cut across the grain of one piece of wood to accommodate the end of another piece. It’s widely used for its strength and precision in creating shelves, cabinets, and drawer construction.

- Complexity: Moderate

- Strength: High

- Skill Level Required: Intermediate

- Tools Required: Specialized (table saw, dado blade set, router)

- Aesthetic Appeal: Low to moderate; typically hidden in final assembly

- Common Uses: Shelving, cabinet making, drawer construction

- Load Bearing Capacity: High; provides a large surface area for glue

- Time to Create: Moderate

- Material Suitability: Primarily wood

- Glue Surface Area: High; the dado provides a large area for adhesive

- Fastening Method: Glue, sometimes supplemented with screws or nails

- Durability: High; dado joints create a strong bond resistant to pulling and stress

- Special Considerations: Requires precise measurements and cuts for a snug fit; ideal for creating stable, permanent connections in woodworking projects.

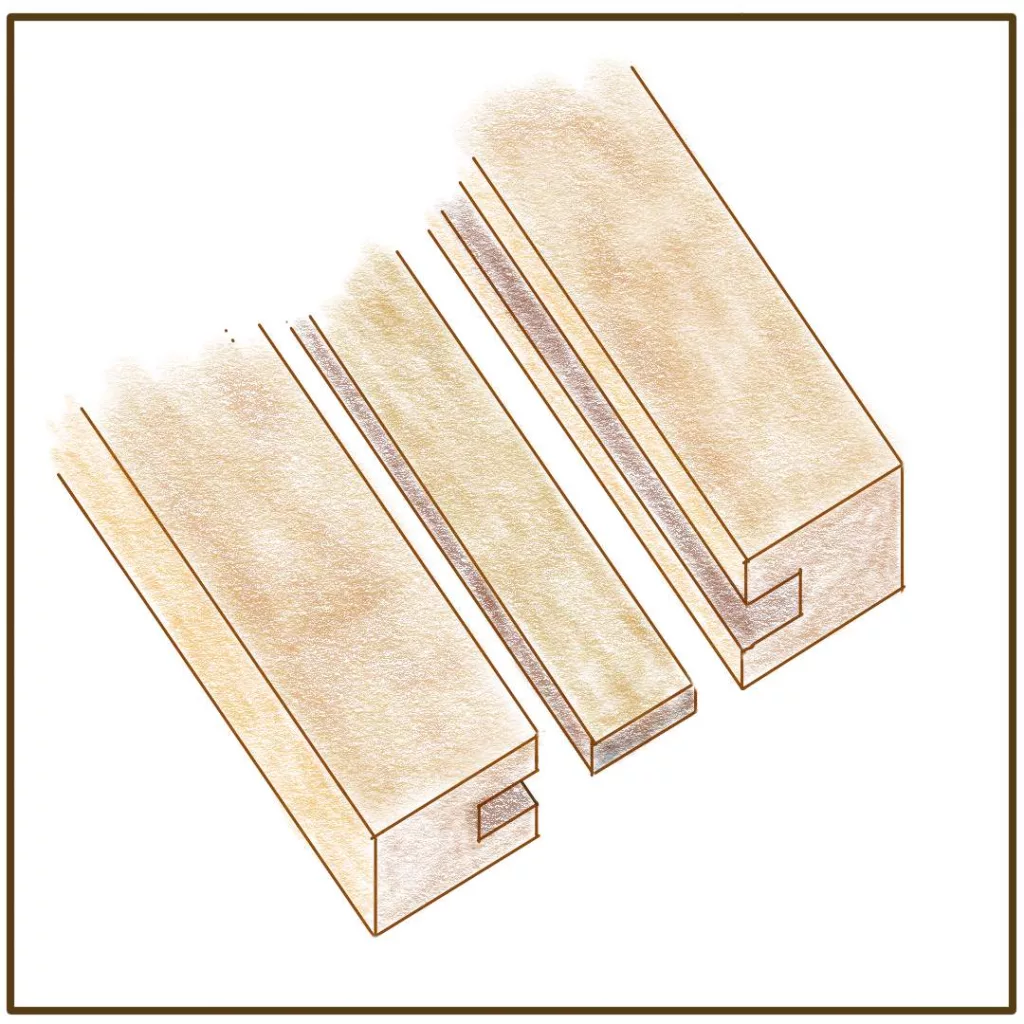

Rabbet Joint

The Rabbet Joint is a versatile and straightforward woodworking technique where a recess or groove is cut into the edge of one piece of wood to accept the end of another piece. It’s commonly used for its simplicity and effectiveness in box constructions, cabinetry, and framing.

- Complexity: Simple

- Strength: Moderate

- Skill Level Required: Beginner to Intermediate

- Tools Required: Basic to specialized (hand plane, table saw, router)

- Aesthetic Appeal: Moderate; often visible but can be designed for a clean finish

- Common Uses: Cabinet backs, drawer construction, picture frames

- Load Bearing Capacity: Moderate; provides a good amount of surface area for glue

- Time to Create: Quick to moderate

- Material Suitability: Primarily wood

- Glue Surface Area: Moderate; the rabbet increases the area for adhesive

- Fastening Method: Glue, often combined with nails or screws

- Durability: Moderate to high; depends on the application and materials used

- Special Considerations: Ideal for creating joints in box-shaped projects; can be easily combined with other joints for added strength and complexity.

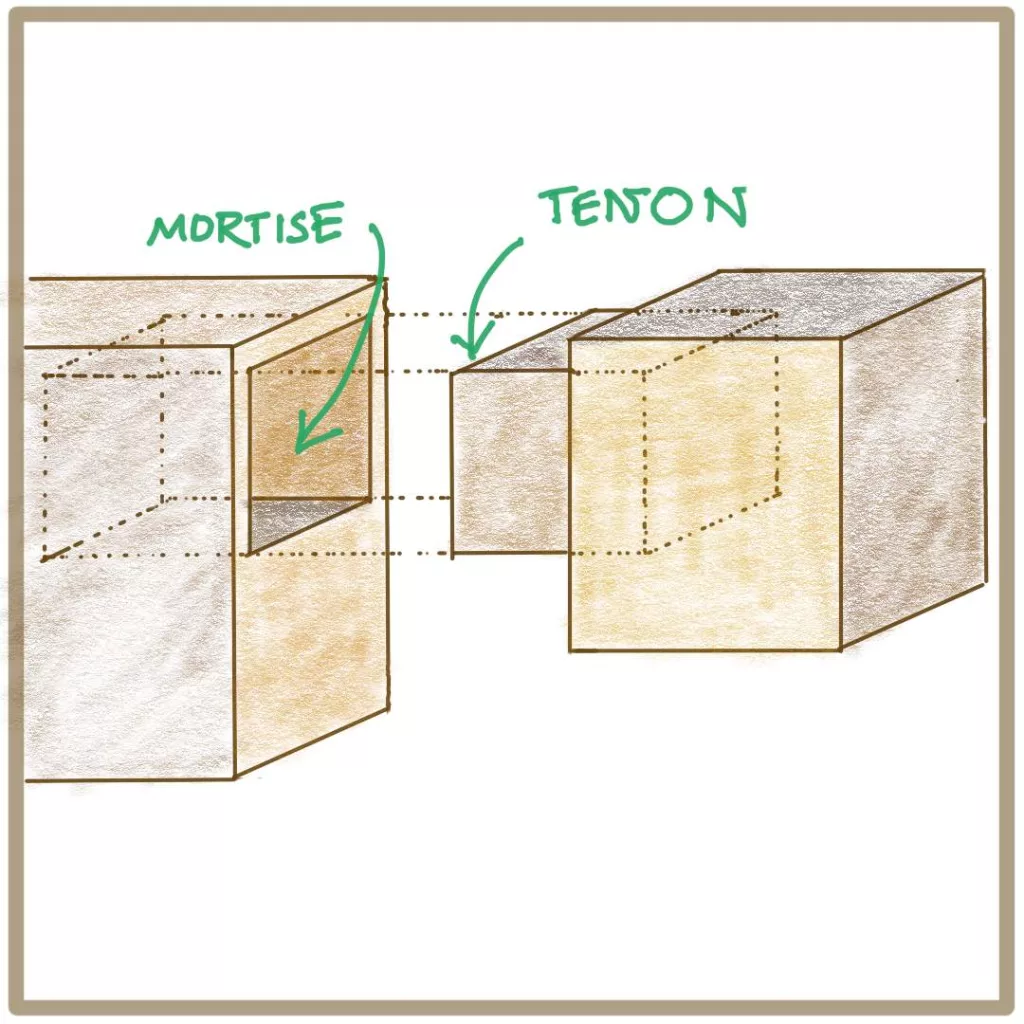

Mortise and Tenon Joint

The Mortise and Tenon Joint is a classic and highly respected woodworking joint, characterized by a tenon (a projecting piece of wood) fitting snugly into a mortise (a corresponding recess). This joint is renowned for its strength and stability, making it a staple in traditional and modern woodworking for structural connections.

- Complexity: Moderate to High

- Strength: High

- Skill Level Required: Intermediate to Advanced

- Tools Required: A range from basic (chisels, saws) to specialized (mortising machines, tenon jigs)

- Aesthetic Appeal: High; often highlighted in design for its craftsmanship

- Common Uses: Furniture making, door and window frames, timber framing

- Load Bearing Capacity: High; excellent for load-bearing structures

- Time to Create: Moderate to time-consuming, depending on the complexity

- Material Suitability: Primarily wood

- Glue Surface Area: High; the interlocking nature provides a large area for adhesive

- Fastening Method: Primarily glue; can be reinforced with pins or wedges

- Durability: Very high; one of the strongest woodworking joints

- Special Considerations: Requires precise measurement and cutting for a proper fit; ideal for applications where strength and longevity are paramount.

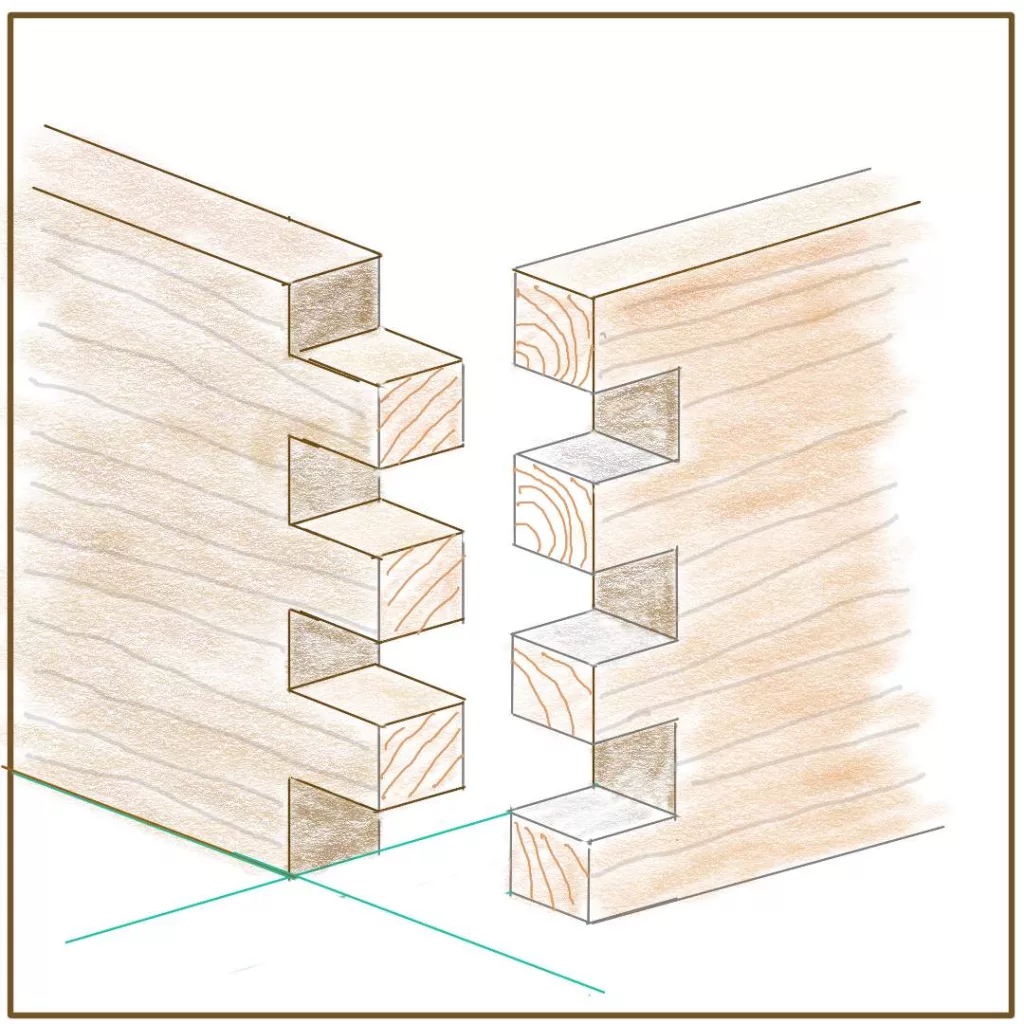

Finger Joint

The Finger Joint, also known as a Box Joint, is a popular woodworking technique characterized by a set of complementary rectangular cuts that join two pieces of wood at their ends. It is highly valued for its simplicity and strength, particularly in box or frame construction.

- Complexity: Moderate

- Strength: High

- Skill Level Required: Intermediate

- Tools Required: Specialized (table saw or router with a finger joint jig)

- Aesthetic Appeal: Moderate to High; can be decorative with precise craftsmanship

- Common Uses: Box construction, drawer making, cabinetry

- Load Bearing Capacity: High; provides a large surface area for glue

- Time to Create: Moderate

- Material Suitability: Primarily wood

- Glue Surface Area: High; interlocking fingers increase the area

- Fastening Method: Glue, rarely requires additional fasteners

- Durability: High; the interlocking nature ensures a strong bond

- Special Considerations: Requires accurate cuts for a snug fit; ideal for creating strong corners in woodworking projects.

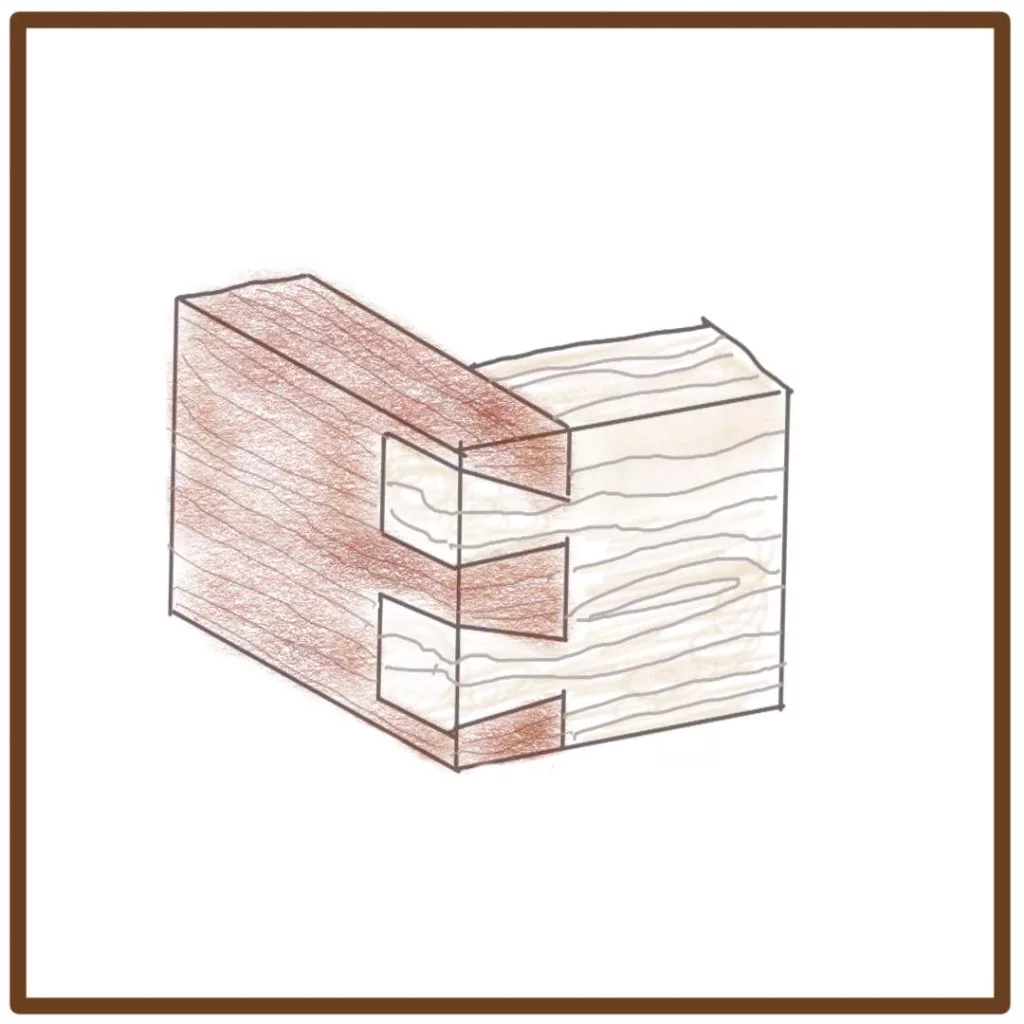

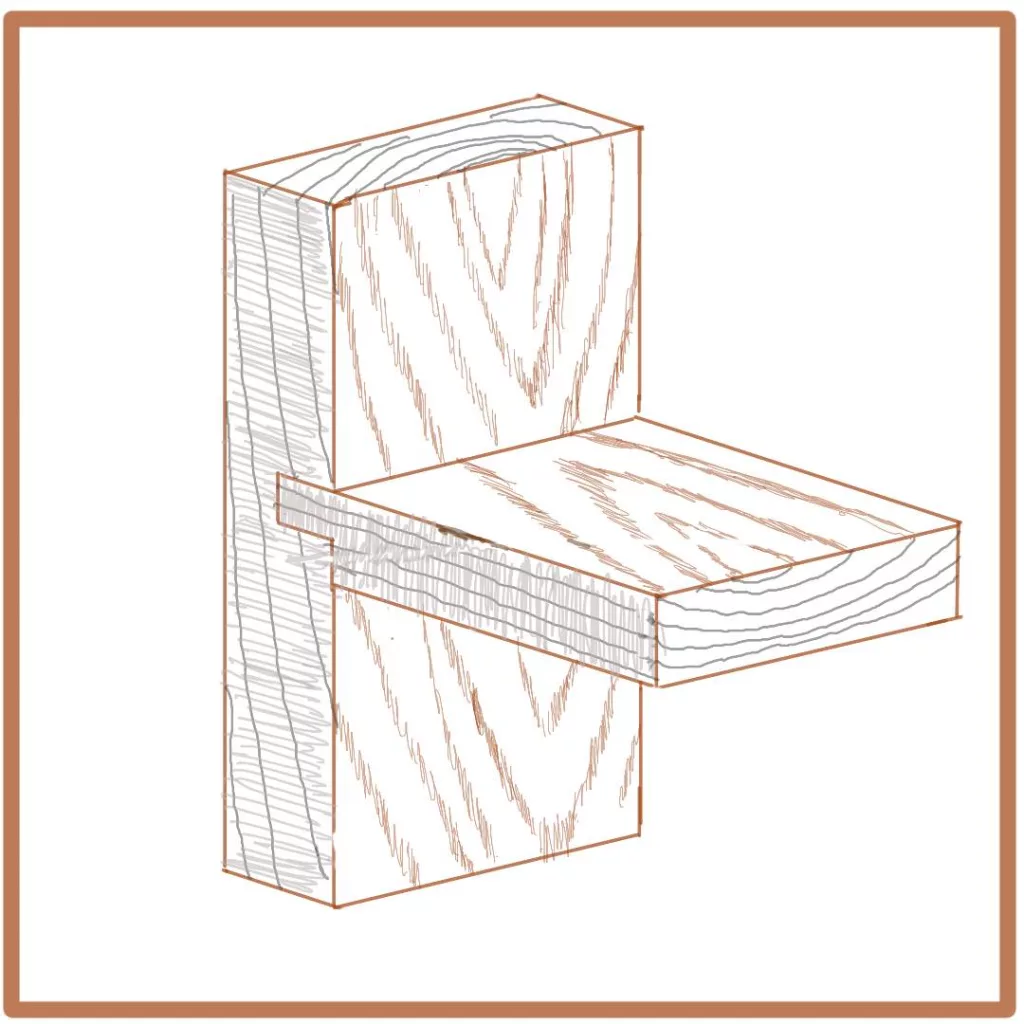

Bridle Joint

The Bridle Joint is a traditional woodworking joint, similar to a mortise and tenon, involving a tenon on one piece that fits into a mortise-like slot on the other piece. This joint is appreciated for its balance of strength and simplicity, commonly used in framework and carpentry.

- Complexity: Moderate

- Strength: High

- Skill Level Required: Intermediate

- Tools Required: Basic to specialized (saws, chisels, possibly a router)

- Aesthetic Appeal: Moderate; often used in areas where the joint is visible and part of the design

- Common Uses: Framework, gates, timber framing, and traditional joinery

- Load Bearing Capacity: High; especially effective in tension and compression

- Time to Create: Moderate

- Material Suitability: Primarily wood

- Glue Surface Area: High; the slot and tenon provide a substantial area for adhesive

- Fastening Method: Glue, sometimes reinforced with pins or screws

- Durability: High; provides a robust and long-lasting joint

- Special Considerations: Requires precise cutting for a proper fit; ideal for structural connections where strength is a priority.

Lap Joint

The Lap Joint is a versatile and straightforward woodworking connection where two pieces of material overlap each other. It’s favored for its ease of making and reasonable strength, commonly used in framing, cabinetry, and furniture.

- Complexity: Simple to Moderate

- Strength: Moderate

- Skill Level Required: Beginner to Intermediate

- Tools Required: Basic (saw, chisel) to specialized (router)

- Aesthetic Appeal: Moderate; can be designed to be visible or hidden

- Common Uses: Frame construction, cabinetry, table tops

- Load Bearing Capacity: Moderate; better than a butt joint but less than more complex joints

- Time to Create: Quick to moderate

- Material Suitability: Primarily wood

- Glue Surface Area: Moderate; the overlapping area provides a decent surface for glue

- Fastening Method: Glue, nails, or screws

- Durability: Moderate; more durable than a simple butt joint

- Special Considerations: Offers a balance between strength and ease of construction; can be reinforced with mechanical fasteners for additional strength.

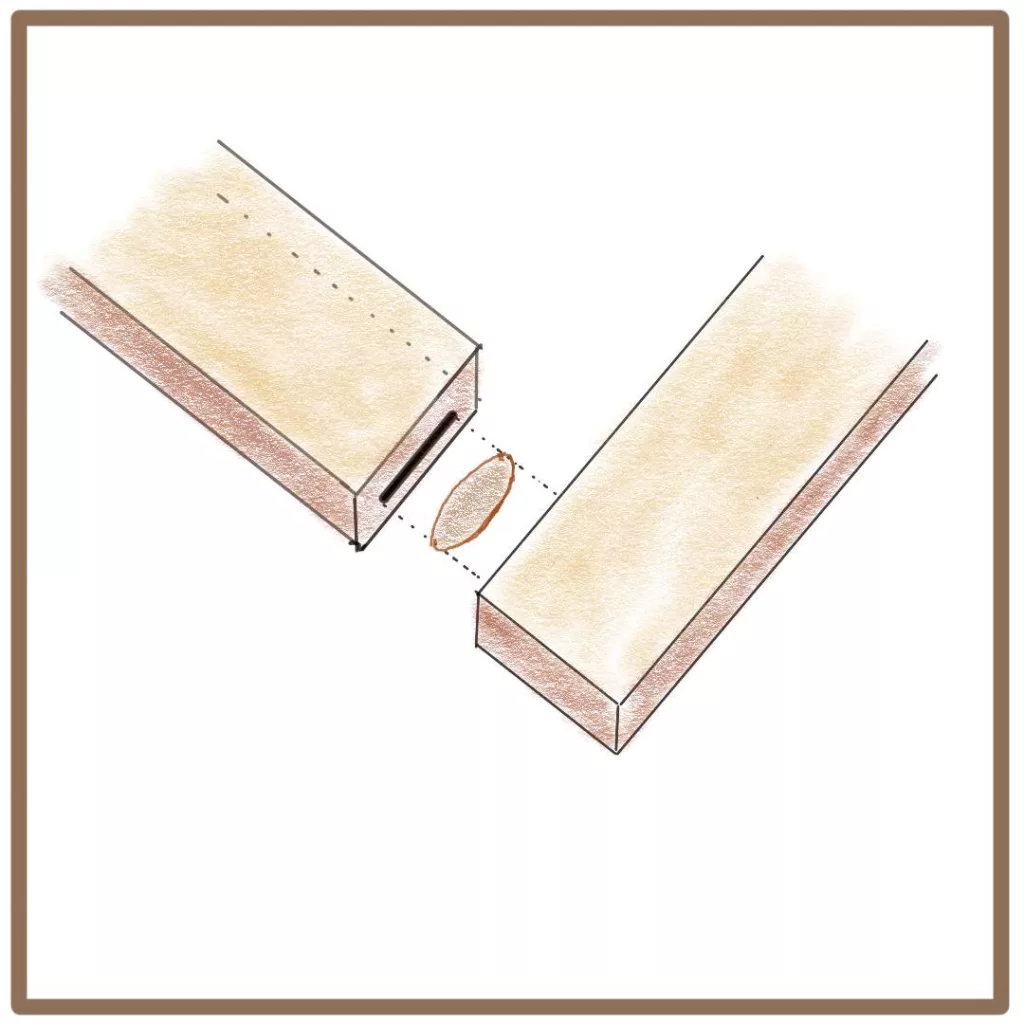

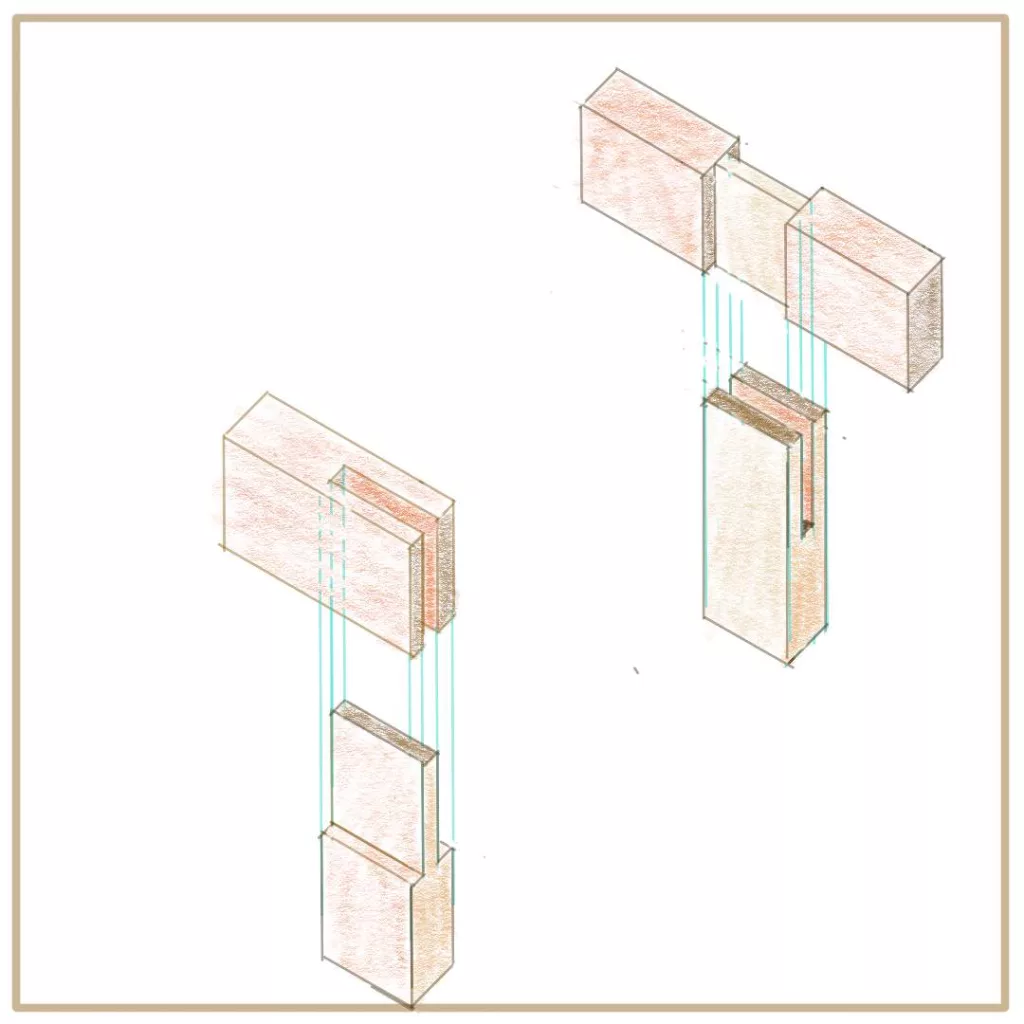

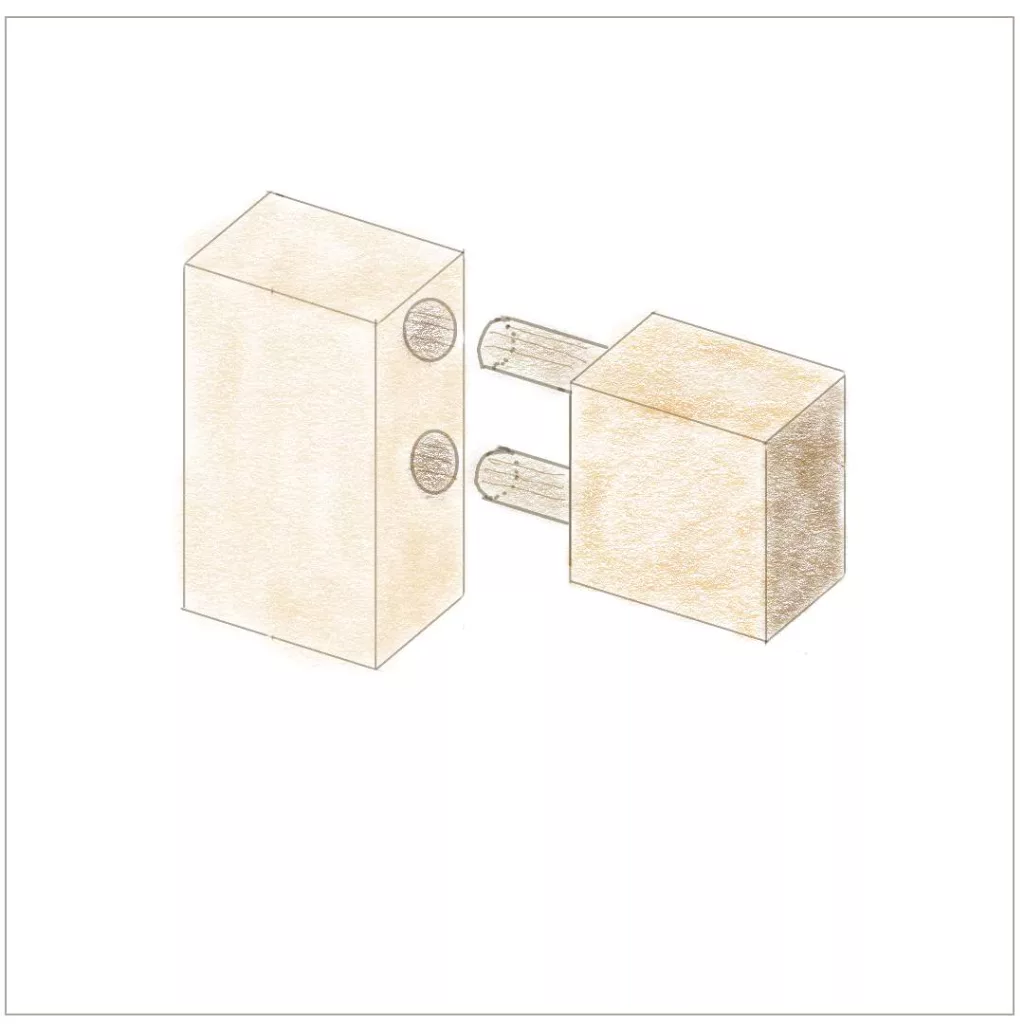

Dowel Joint

The Dowel Joint is a practical and efficient woodworking method where small wooden pins (dowels) are used to align and strengthen the connection between two pieces of wood. It’s favored for its simplicity and effectiveness, particularly in cabinet making and furniture assembly.

- Complexity: Simple to Moderate

- Strength: High

- Skill Level Required: Beginner to Intermediate

- Tools Required: Drill, doweling jig for alignment

- Aesthetic Appeal: Low to Moderate; typically hidden in the finished product

- Common Uses: Furniture assembly, cabinet making, joining panels

- Load Bearing Capacity: High; dowels add significant strength to the joint

- Time to Create: Quick to moderate

- Material Suitability: Primarily wood

- Glue Surface Area: Moderate to High; dowels increase the glued surface area

- Fastening Method: Glue and wooden dowels

- Durability: High; dowels provide additional reinforcement

- Special Considerations: Requires precise drilling for alignment; ideal for reinforcing joints without altering the external appearance of the pieces.

Groove Joint

The Groove Joint, a fundamental woodworking technique, involves creating a slot or groove along the grain of one piece to accept another piece. It’s widely used for its simplicity and effectiveness in panel construction and cabinetry.

- Complexity: Simple to Moderate

- Strength: Moderate

- Skill Level Required: Beginner to Intermediate

- Tools Required: Basic to specialized (router, table saw)

- Aesthetic Appeal: Low to Moderate; often hidden in the final assembly

- Common Uses: Paneling, flooring, drawer bottoms, and cabinet backs

- Load Bearing Capacity: Moderate; provides a decent surface area for glue

- Time to Create: Quick to moderate

- Material Suitability: Primarily wood

- Glue Surface Area: Moderate; the groove provides a good area for adhesive

- Fastening Method: Glue, sometimes supplemented with nails or screws

- Durability: Moderate; suitable for many types of joinery

- Special Considerations: Requires accurate measurements and cuts for a proper fit; ideal for creating stable, flush connections in woodworking projects.

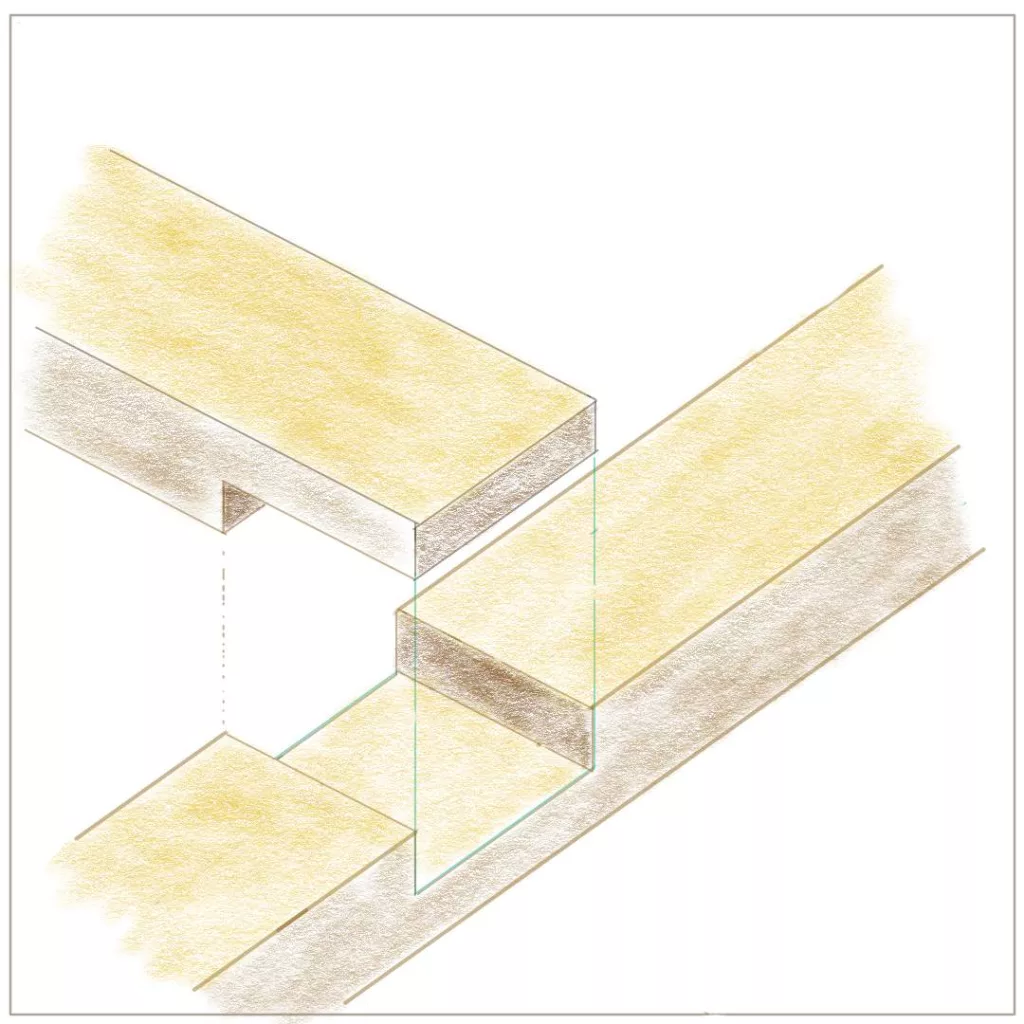

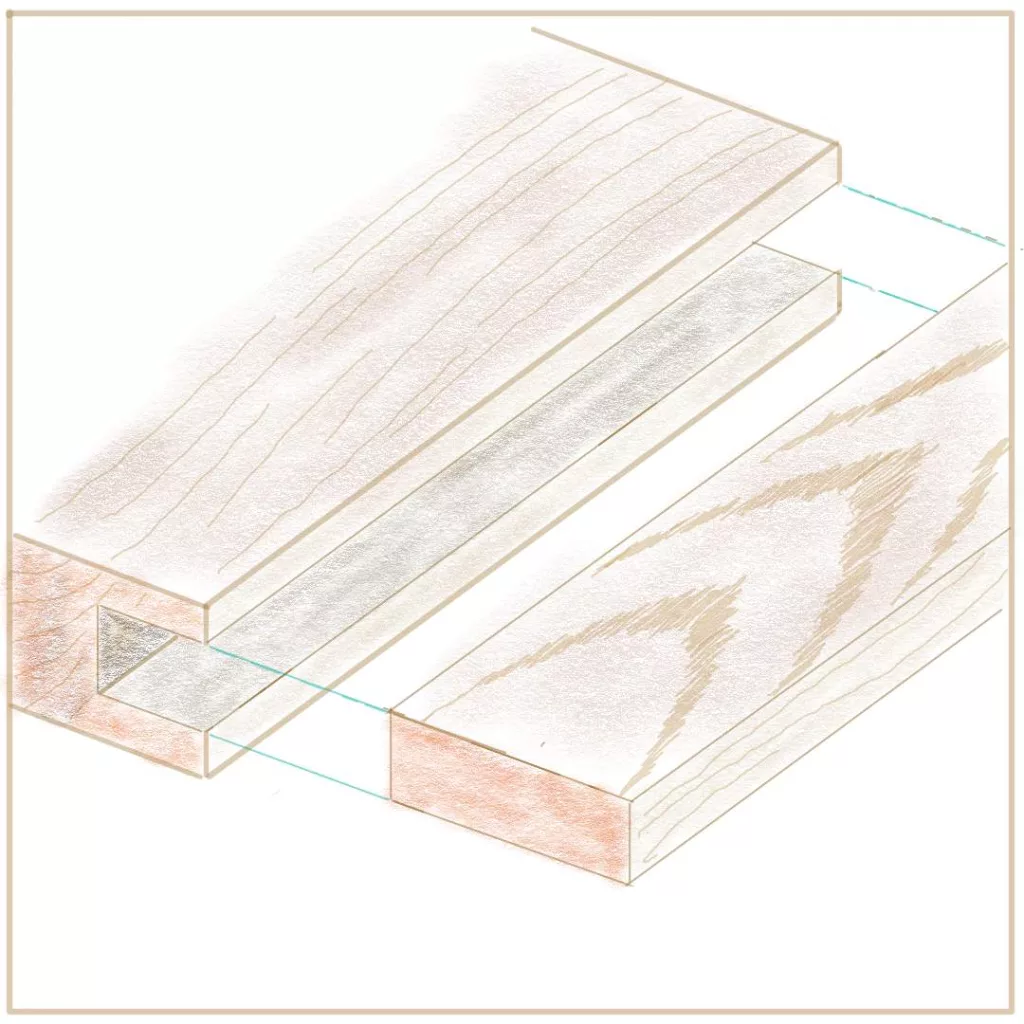

Tongue and Groove Joint

The Tongue and Groove Joint is a classic and durable woodworking method where a protruding ‘tongue’ on one piece fits snugly into a ‘groove’ on another. This joint is renowned for its ability to align and connect panels seamlessly, making it a staple in flooring, paneling, and cabinet making.

- Complexity: Moderate

- Strength: Moderate to High

- Skill Level Required: Intermediate

- Tools Required: Router, table saw with dado blades

- Aesthetic Appeal: High; provides a smooth, continuous surface

- Common Uses: Flooring, paneling, cabinet doors, and tabletops

- Load Bearing Capacity: Moderate; excellent for lateral strength

- Time to Create: Moderate

- Material Suitability: Primarily wood, some composites

- Glue Surface Area: Moderate; the tongue and groove increase the glued area

- Fastening Method: Glue, with or without mechanical fasteners

- Durability: High; ensures a tight and long-lasting fit

- Special Considerations: Requires precise machining for a proper fit; ideal for creating large, stable surfaces with minimal visible seams.

Groove Joint VS Tongue and Groove Joint

It is interesting to know the differences of these two.

| Feature | Groove Joint | Tongue and Groove Joint |

|---|---|---|

| Construction | Single groove or slot cut into one piece of wood | ‘Tongue’ on one edge fits into ‘groove’ on another piece |

| Application | Accepts a flat edge of another piece; used in cabinetry and paneling | Used in flooring, paneling for long, continuous surfaces |

| Function | Positions and secures a panel within the grooved piece | Interlocking design aligns and holds pieces together |

| Strength | Moderate, mainly for alignment and securing panels | Higher, resists pulling apart and lateral movement |

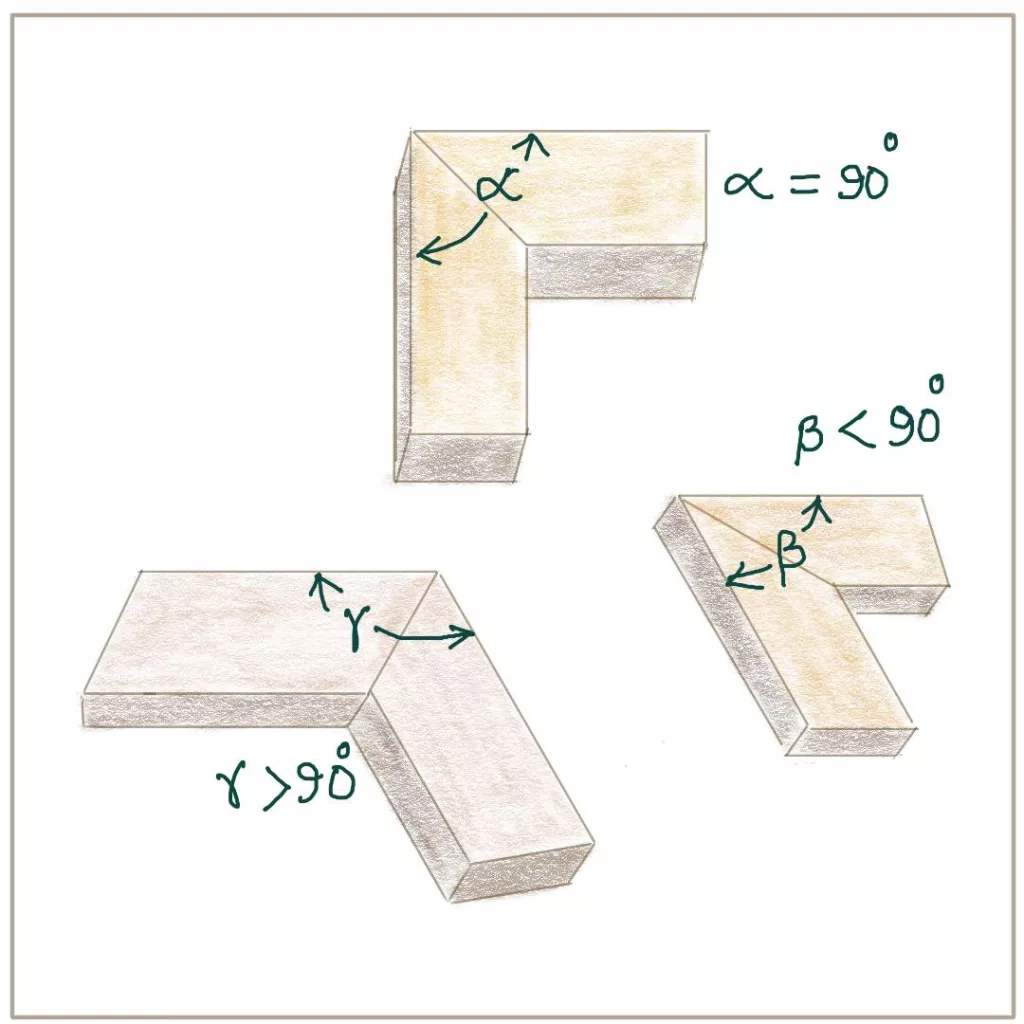

Miter Joint

The Miter Joint is an elegant and commonly used woodworking technique where two pieces are cut at an angle (typically 45 degrees, but it may vary) and joined together. This joint is particularly favored for its aesthetic appeal in frames and decorative applications.

- Complexity: Simple to Moderate

- Strength: Low to Moderate

- Skill Level Required: Beginner to Intermediate

- Tools Required: Miter saw or hand saw with a miter box

- Aesthetic Appeal: High; provides a seamless and attractive corner

- Common Uses: Picture frames, door and window trim, decorative moldings

- Load Bearing Capacity: Low; not suitable for heavy loads without reinforcement

- Time to Create: Quick

- Material Suitability: Wood, some plastics, and light metals

- Glue Surface Area: Low; end grain to end grain contact

- Fastening Method: Glue, often reinforced with nails, screws, or splines

- Durability: Moderate; depends on reinforcement and application

- Special Considerations: Precision in cutting angles is crucial for a tight fit; often reinforced for added strength and stability.

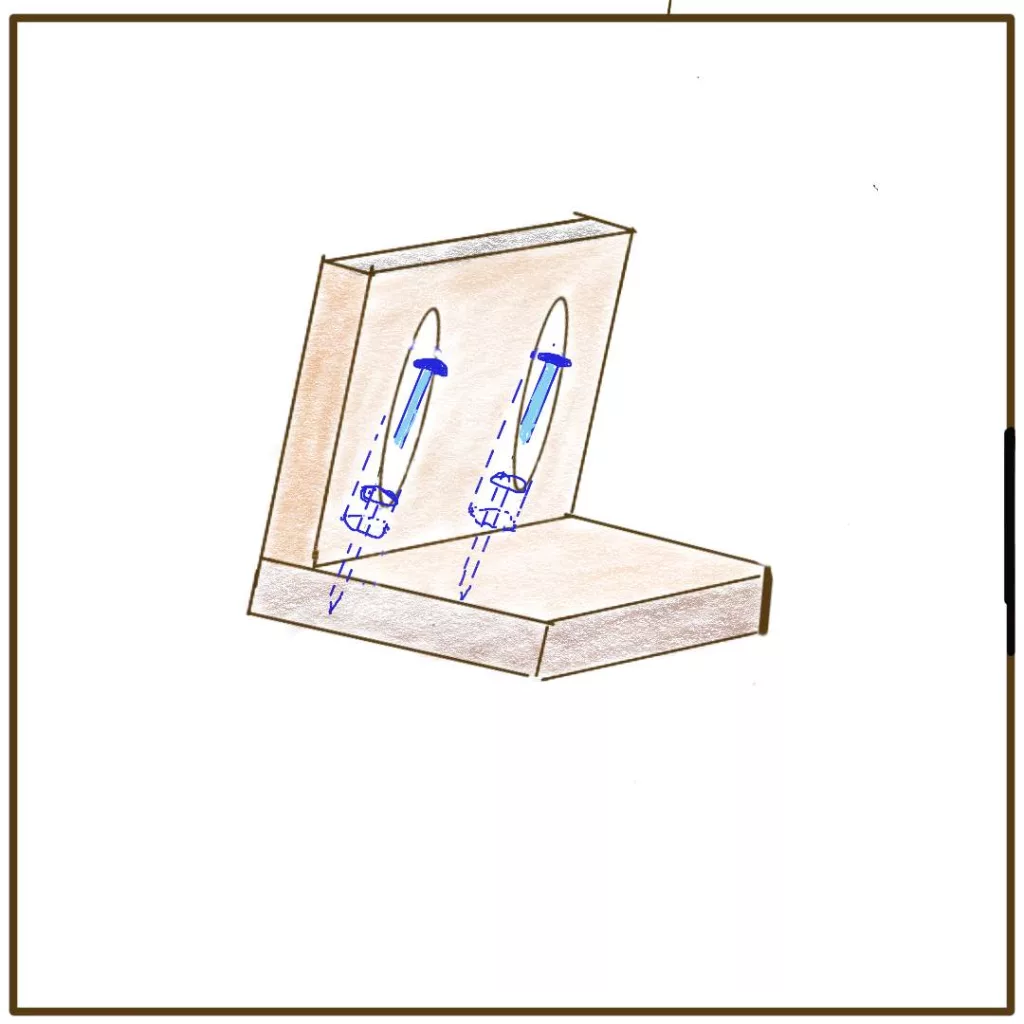

Pocket-Hole Joint

The Pocket-Hole Joint is a practical and efficient woodworking method where angled holes are drilled into one piece of wood, and screws are driven into these holes to join another piece. This technique is highly valued for its ease of use and strong, reliable connections, especially in furniture making and cabinetry.

- Complexity: Simple

- Strength: High

- Skill Level Required: Beginner to Intermediate

- Tools Required: Specialized (pocket-hole jig, drill, screws)

- Aesthetic Appeal: Low; typically hidden in the final assembly

- Common Uses: Furniture assembly, cabinetry, frame construction

- Load Bearing Capacity: High; provides a strong and stable joint

- Time to Create: Quick

- Material Suitability: Primarily wood

- Glue Surface Area: Low; relies more on mechanical strength

- Fastening Method: Screws specifically designed for pocket-hole joinery

- Durability: High; creates a robust and long-lasting joint

- Special Considerations: Ideal for quick and sturdy construction; the use of a pocket-hole jig ensures precise and consistent hole placement.

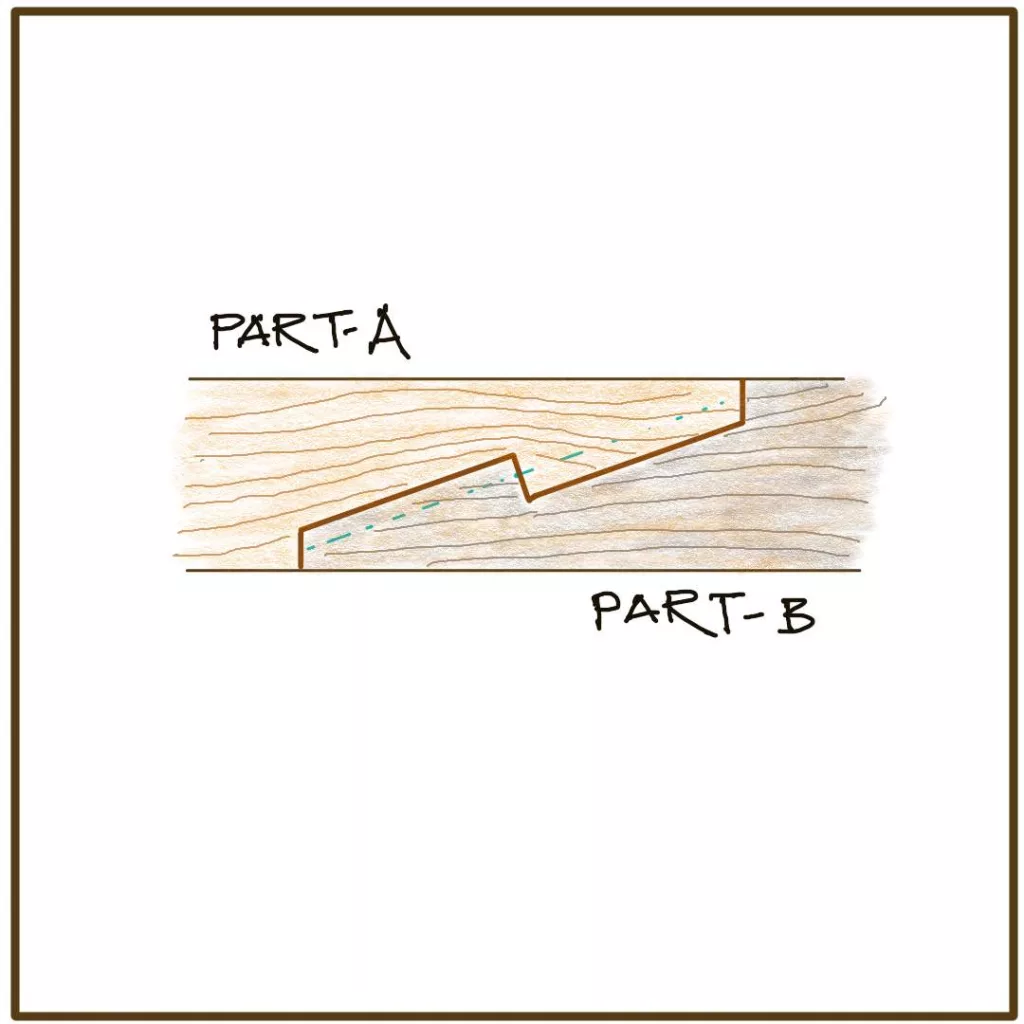

Scarf Joint

The Scarf Joint is an intricate and effective woodworking technique used to join two pieces end-to-end, typically involving beveled cuts on each piece that fit together. This joint is particularly valued for its strength and subtlety in applications where a long, continuous piece is needed.

- Complexity: Moderate to High

- Strength: High

- Skill Level Required: Intermediate to Advanced

- Tools Required: Hand saw, power saw, or plane for precise bevel cuts

- Aesthetic Appeal: High; creates a nearly invisible joint when done correctly

- Common Uses: Long beams in construction, boat building, and in any situation where a long, continuous piece of wood is required

- Load Bearing Capacity: High; especially effective for tensile and compressive forces

- Time to Create: Moderate to time-consuming, depending on the complexity

- Material Suitability: Primarily wood

- Glue Surface Area: High; the beveled cuts increase the area for adhesive

- Fastening Method: Glue, often reinforced with nails, screws, or dowels

- Durability: High; provides a strong and seamless connection

- Special Considerations: Requires accurate cutting and fitting; ideal for structural applications where joint visibility is a concern.

You can watch this basic joinery video.

More Reads

- Woodworking basics

- Foundations of Woodworking: Essential joinery techniques and building strategies by Michael Pekovich; ISBN-13 : 978-1641551625.

Conclusion

The evolution of wood joining techniques, from traditional hand-cut methods to modern machine-aided processes, reflects the adaptability and innovation in woodworking. Regardless of the method, the goal remains the same: to create strong, durable, and often aesthetically pleasing connections between pieces of wood. The art and science of wood joining continue to be a vital and evolving aspect of woodworking, blending tradition with modern technology.