How to Preserve Wood: Amazing Techniques

Any woodworking unveils the quintessential bond between mankind and wood, a relationship nurtured over centuries. The phrase “how to preserve wood” echoes a significant endeavor in this bond, embodying the collective efforts to uphold wood’s natural elegance and structural prowess, which forms the core of myriad creations, standing testament to human ingenuity.

Yet, nestled within its grains lies a vulnerability to the relentless march of time, the encroachment of pests, and the invasive essence of moisture. The quest to shield this noble material from such adversaries leads us to the domain of wood preservation, a blend of age-old wisdom and modern-day innovation.

How to Preserve Wood: A Holistic Approach

Preserving wood is a omni-directional approach towards wood. It involves making the material impregnable from insects, moisture, fungi and all the decaying influencers. And it encompass treatment, sealing, and sometimes finishing to extend wood’s lifespan.

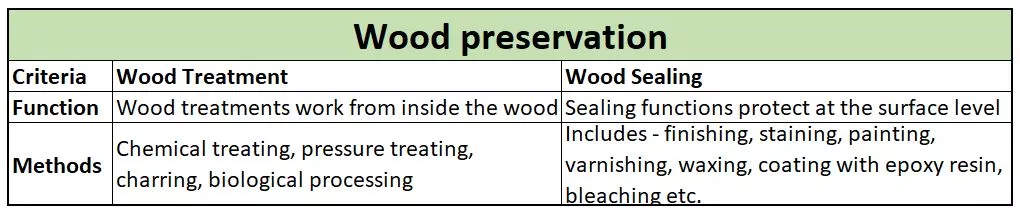

| Treatment | Sealing |

| It is the application of chemicals or substances to boost resistance inside the wood against pests, rot, and external factors | It is the application of protective coating to deter moisture infiltration, and make a protective barrier against pests, UV rays and fungi. |

| Includes – chemical treating, pressure treating, charring, biological processing. | Includes – finishing, staining, painting, varnishing, waxing, coating with epoxy resin, bleaching etc. |

During a project in 2018, I observed how applying a sealant created a barrier that locked out moisture, providing the wood with an added layer of protection.

How Treatment and Sealing Work Together

In essence, wood treatments work from inside the wood, and sealing functions protect at the surface level. While there’s some overlap in their functions, treatment generally deals with deep, internal protection, targeting a broader range of threats, whereas sealing focuses on surface protection, moisture prevention, and aesthetics.

Wood Treatment: Primary Task for Preservation

- Treatment often precedes more thorough preservation methods, e.g., borate treatment before moisture-resistant coating in a restoration project.

- Pre-treatments can neutralize fungi and pests, ensuring a safer surface for sealants.

- Certain treatments stabilize wood, minimizing its tendency to warp or crack, thereby enhancing the longevity of subsequent sealants.

- Proper treatment can prolong wood lifespan by 5 to 50 years, varying with treatment type and wood species.

Features of Wood Treatment

- Internal Protection: Treatments generally penetrate deeper into the wood to protect it from the inside. They can be infused into the wood through processes like pressure or dip treatments.

- Broad Protection: Treatment aims to defend wood against a wide range of threats, including insects, fungi, bacteria, and more. For example, pressure-treated wood is resistant to termites and fungal decay.

- Chemicals & Natural Agents: Wood can be treated using a variety of chemicals, like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ), as well as natural agents like borates.

- Long-Term Focus: Treatments, especially when combined with sealants, can offer long-term protection against decay and pests.

Sealing as a Preservation Task

- Sealants often contain UV inhibitors, offering protection against the sun’s harmful rays.

- The sealing process locks in essential oils and resins in wood, prolonging their natural protective effects.

- Beyond mere protection, sealing often provides wood with a lustrous finish, amplifying its natural grain and beauty.

- Proper sealing can reduce wood’s susceptibility to swelling or shrinking with changing humidity levels.

Features of Wood Sealing/ Importance of Sealing in Wood Preservation

- Surface Protection: Sealants primarily create a barrier on the surface of the wood, making it less susceptible to external factors like moisture, UV rays, and surface-dwelling pests.

- Moisture Barrier: One of the primary functions of a sealant is to prevent moisture ingress. This can help reduce swelling, warping, and rot.

- Visual Enhancement: While some treatments can change the appearance of wood (like stains), sealants, especially finishes like varnishes and lacquers, can enhance the wood’s natural beauty and grain.

- Re-application Needs: Sealants might need to be reapplied periodically, especially if they are exposed to harsh weather conditions or heavy wear and tear.

- Color and Texture Preservation: Sealants help in retaining the wood’s color and texture by preventing discoloration and surface erosion, contributing to a polished and refined appearance.

Treating Wood for Preservation

Wood treatment encompasses various techniques to enhance the durability and lifespan of wood by safeguarding it from detrimental factors like insects, fungi, and decay. This crucial step ensures that wood retains its functional and aesthetic attributes over time. I will go through a number of ways to preserve wood.

Chemical Wood Preservatives – Applied in Various Processes

Chemical treatment methods involve applying substances or chemicals to wood to protect it from pests, rot, and other external factors. These methods are highly effective in extending the wood’s life and maintaining its quality over time.

Pressure Treating

Pressure treating is a commonly adopted method to impregnate wood with chemical preservatives, making it resilient to insects, fungi, and other decay agents.

These chemicals are used in pressure treating –

- Alkaline Copper Quaternary (ACQ)

- Copper Azole (CA)

- Chromated Copper Arsenate (CCA)

- Borates (SBX, DOT)

- Micronized Copper Azole (MCA)

- Creosote

- Pentachlorophenol

- Light Organic Solvent Preservatives (LOSP)

Equipment and Safety Measures

The core of pressure treating is the use of specialized equipment like pressure chambers. Ensuring safety is paramount, with strict protocols to handle and dispose of chemicals properly to avert any potential hazards.

Benefits and Limitations

This method significantly extends the wood’s lifespan, albeit at a higher upfront cost. While effective, the chemicals used can be hazardous, necessitating careful handling.

Dip Treating

Dip treating is another method where wood is submerged in a chemical solution to enhance its durability, a simpler alternative to pressure treating.

Procedure and Effectiveness

The wood is immersed in a chemical bath for a specified duration, allowing the preservative to penetrate the wood. Its effectiveness is generally lower than pressure treating but serves well for certain applications.

Chemicals Used

Various chemicals can be utilized in dip treating, like copper or boron compounds, each with its distinct advantages and disadvantages concerning effectiveness and environmental impact. Following are the chemical wood preservers mostly used in dip treating –

- Copper Naphthenate

- Boron Compounds (such as Borates, Disodium Octaborate Tetrahydrate)

- Zinc Naphthenate

- Permethrin

- Quaternary Ammonium Compounds (QACs or Quats)

- IPBC (Iodopropynyl Butylcarbamate)

- Chromated Copper Arsenate (CCA, although its use has been restricted due to environmental concerns)

Heat Treatment

Heat treatment alters the wood’s chemical composition through controlled heating, enhancing its resistance to decay organisms without the use of chemicals.

Process Overview

Specialized kilns are employed for heat treatment, with modern technology ensuring uniform temperature control for optimum treatment. Wood is heated in a controlled environment at high temperatures (typically between 160°C to 215°C or 320°F to 419°F) for a specific duration. The process changes the wood’s structure, making it less appealing to pests and more durable.

Advantages and Challenges

Heat treatment is eco-friendly in a sense, and avoids chemical usage. However, it can be costly and may alter the wood products’ colors and mechanical properties.

Biological Control Agents

Employing biological agents like beneficial fungi or insects is an innovative, eco-friendly method to curb wood-decaying organisms. Following biological entities you can use for treatment.

- Trichoderma species (beneficial fungi)

- Bacillus thuringiensis (beneficial bacteria)

- Nematodes (beneficial microscopic worms)

- Ladybugs and predatory beetles (beneficial insects)

These biological agents can provide a level of protection against harmful organisms, although their effectiveness can vary and may not match that of chemical treatments.

Moreover, any wood with oil has a level of natural protection against moisture (oils are water repellent or hydrophobic), insects, fungi; in other words, rot and decay. Teak and red cedar have have natural oil contents (extractives) and are naturally self-protective to some extent. Tannins, resins, quinones improve natural durability as well.

Mechanism of Action

Biological agents prey on or compete with harmful organisms, providing a natural defense mechanism for the wood.

Available Agents and Their Efficacy

A variety of agents are available, their efficacy varies, and the choice depends on the specific wood threats and environmental considerations.

Environmental Impact

Biological control is considered environmentally benign, reducing the reliance on chemicals, thereby promoting a healthier ecosystem.

Shou Sugi Ban (Charring)

- Shou Sugi Ban, or Yakisugi, is a traditional Japanese method aimed at preserving wood by charring its surface.

- This technique not only enhances the durability of the wood but also imparts a unique aesthetic appeal.

- It can be applied on untreated wood.

Process

- The process involves meticulously charring the surface of the wood, usually with a torch, until it turns black.

- Once charred, the wood is cooled down and cleaned to remove loose char.

- Finally, a layer of natural oil is applied to seal the wood and enhance its appearance.

Benefits

- Shou Sugi Ban creates a protective layer that deters pests (works against insect attack), resists fire, and prevents decay.

- The charred surface is low-maintenance and can endure for many years without requiring further treatment.

Applications

- This treatment is used in many contemporary architectural projects for exterior and interior cladding.

- Shou Sugi Ban treated wood is appreciated for its natural, elegant aesthetic and robustness, making it a favored choice for various design and building applications.

Through understanding and combining these methods effectively, one can significantly extend the life and maintain the quality of wood, making it a sustainable choice in construction and other applications.

You can read Shou Sugi Ban here for more details.

Sealing Wood for Extended Longevity

As a wood enthusiast with over a decade of experience, I’ve come to appreciate the transformative power of a well-applied sealant. Whether I was working on a quaint outdoor deck or restoring an antique piece of furniture, the sealing phase was a game-changer, significantly bolstering the wood’s defense against the elements while reinforcing its natural charm.

Sealing steps in brief:

- Step 1: Selection of Appropriate Sealant

- Step 2: Prepare the Wood Surface

- Cleaning

- Sanding with coarse grit (80-100 grit)

- Dusting off

- Step 3: Application of Primer (if necessary)

- Step 4: Application of First Sealant Coat

- Step 5: Drying Period

- Step 6: Light Sanding with medium grit (150-180 grit)

- Step 7: Application of Second Sealant Coat

- Step 8: Drying and Curing

- Step 9: Inspection for Coverage

- Step 10: Additional Coats (if necessary)

- Step 11: Final Drying and Curing

- Step 12: Final Inspection and Touch-ups

Factors Affecting Sealing Efficiency

The efficiency of sealing depends on factors like the type of sealant used, the application method, and the wood’s condition.

- Type of Sealant or Sealer Type: The choice of sealant plays a pivotal role in the sealing efficiency. Different sealants offer varied levels of protection and finish, catering to diverse wood sealing needs.

- Application Method: The method employed to apply the sealant also impacts the sealing efficiency. Techniques like brushing, spraying, or wiping have their own set of advantages and are suited for different project requirements.

- Wood Condition: The condition of the wood at the time of sealing significantly affects the efficiency of the process. It’s essential to ensure that the wood is clean, dry, and free from any decay or damage.

- Preparation: Adequate preparation of the wood surface, including cleaning and sanding, is crucial for ensuring the sealant adheres properly and performs as expected.

- Environmental Conditions: The temperature and humidity levels at the time of application can affect the drying time and the performance of the sealant.

- Maintenance: Regular maintenance, including cleaning and re-sealing as necessary, helps to retain the efficiency of the sealing, prolonging the wood’s longevity.

- Manufacturer’s Instructions: Following the manufacturer’s instructions for application and maintenance ensures optimal sealing efficiency and performance over time

Types of Wood Sealants

Various sealants cater to different preservation needs. Selecting the right type is pivotal for achieving the desired protection and aesthetic outcome. Following are the sealant types –

- Varnishes

- Lacquers

- Paints

- Oil-Based Sealants

- Water-Based Sealants

- Shellac

- Polyurethane

- Epoxy Sealants

- Wax

- Stains and Finishes

- UV Resistant Sealants

Here’s another video on pressure treatment.

You can have a look into this article for wood sealing as well.

Indoors vs Outdoors Wood Preservation

Preserving wood effectively requires an understanding of the environmental conditions to which it will be exposed. The dichotomy between indoor and outdoor settings lays the groundwork for tailored preservation strategies that meet the distinct challenges posed by each environment.

Environmental Factors

The ambient conditions greatly influence the choice of preservation technique. While weather exposure is a predominant concern for outdoor wood, indoor wood encounters different adversaries like fluctuations in temperature and humidity.

Weather Exposure and Its Effect

Outdoor wood is continually at the mercy of the elements. The sun’s ultraviolet rays, incessant rain, and the bitter cold can hasten the wood’s degradation.

My own patio renovation project was a stark lesson in how unrelenting weather can ravage wood, necessitating a robust sealing and staining regimen to reclaim its former allure.

Indoor Humidity and Temperature Considerations

Indoor wood faces a less tumultuous, yet equally demanding environment. The subtler, continual changes in humidity and temperature can warp and crack wood over time. During the restoration of an antique table, I noticed how indoor temperature fluctuations had caused the wood to split, emphasizing the need for a controlled indoor climate and appropriate wood treatments.

Below is a table summarizing the differences in wood preservation considerations for indoor and outdoor uses of the woods.

| Factors | Outdoor Usage | Indoor Usage |

| Environmental Exposure | Has to withstand harsher conditions (rain, snow, sunlight, extreme temperatures). | Sheltered from extreme conditions. |

| Type of Wood | Hardwoods like cedar or redwood. | Softer woods might be more common. |

| Aesthetic Considerations | Durability may be prioritized over aesthetics. | Aesthetics might be more of a priority, enhancing wood’s beauty. |

| Use of Chemical Preservatives | Stronger chemical preservatives for protection against rot and insects. | Milder, possibly non-toxic or water-based treatments preferred. |

| Maintenance Frequency | More frequent maintenance and re-application of preservatives. | Less frequent maintenance required. |

| Cost and Long-term Investment | Higher initial investment due to robust preservation methods. | Lower initial cost but ongoing maintenance might be needed. |

In a personal project to restore a lakeside cabin, I was torn between a pricier high-quality sealant and a budget-friendly option. After exploring real-world cost comparison studies, it was evident that the high-quality sealant, while costlier upfront, was more economical long-term. This experience underscored the importance of such studies in making cost-effective decisions in wood preservation.

Maintenance and Inspection for Preserved Wood

A disciplined maintenance routine is crucial for extending the longevity and preserving the charm of wood structures. This section emphasizes the significance of routine inspections, cleaning, re-sealing, and repairing treated wood, all within a sensible framework of environmental and safety considerations.

Routine Inspections

Routine inspections form the cornerstone of a robust wood preservation strategy, facilitating early detection and rectification of potential issues.

Checklist Creation

Creating a comprehensive checklist lays the groundwork for systematic inspections. This checklist should encapsulate common signs of wood deterioration and seasonal considerations.

Identifying Common Wood Deterioration Signs

Being adept at identifying common signs of wood deterioration, such as fungal growth or pest infestations, is instrumental in mitigating potential damages at their nascent stages. The signs include :

- Rot (Dry rot, Wet rot)

- Mold and Mildew

- Insect Infestations (e.g., termites, wood-boring beetles)

- Discoloration

- Cracking or Splitting

- Warping

- Peeling Paint or Finish

- Wood Pitting

- Fading

- Water Damage or Staining

Seasonal Inspection Guidelines

- Conduct inspections at the beginning and end of each season, especially harsh ones like winter and summer.

- Check for signs of moisture damage after rainy or snowy periods.

- Look for signs of insect infestation during spring and early summer.

- Inspect for discoloration, cracking, or warping caused by sun exposure at the end of summer.

- Verify the integrity of seals and finishes before and after the harsh weather seasons.

- Ensure proper water drainage away from wood structures during spring and fall.

- Monitor areas prone to moisture accumulation or insect activity.

- Check for loose or rusted fasteners, and ensure they’re properly secured.

- Clear away debris and vegetation that may retain moisture against wood surfaces.

- Document findings, compare with previous inspections to track any progressing deterioration.

- Sand the area where wood deterioration occurred.

- Touch-up or re-apply protective coatings as necessary following the inspection.

- Ensure ventilation areas remain unobstructed to prevent moisture buildup.

Conclusion

This voyage through wood preservation unravels a realm bound by tradition, guided by regulation, and spurred on by innovation. The experience gets stronger if you take actions over the knowledge of how to preserve wood. Wood preservation is a balance among safeguarding the natural essence of wood, prolonging its life, and meeting the aesthetic desires. The balance between these elements, under the stern eye of regulatory frameworks, shapes the practice of wood preservation.

FAQs

What causes wood to rot?

Wood rot is caused by fungi that break down wood fibers. Wet rot happens in persistently damp conditions, and the wood often feels soft and spongy. Dry rot, on the other hand, can develop in less damp conditions, but still requires some moisture. Both types are accelerated in areas with poor ventilation.

How do you preserve wood naturally?

Use natural oils like linseed or tung oil, which nourish the wood and provide a protective barrier against moisture.

How do you make wood last longer?

Regularly clean, treat with appropriate sealants or preservatives, protect from excessive moisture, and ensure proper ventilation for the wood environment.

How do you keep untreated wood from rotting?

Keep it dry, elevate it off the ground, use natural oils for protection, and consider periodic applications of natural anti-fungal solutions like vinegar.