Exploring 14 Physical Properties of Wood: A Comprehensive Analysis of Key Characteristics

Physical properties are characteristics that can be observed or measured without changing the substance’s identity. From the rich, tactile textures to its myriad shades, wood has been an integral part of human civilization’s tapestry. This isn’t just about aesthetics, though.

The framework of cellulose fibers, bound by lignin, creates wood’s distinct physical properties. These characteristics define everything: the tonal beauty of a guitar, the resilience of a century-old home, and the warmth of a handcrafted wooden mug.

Physical Properties of Wood

Hardness or Density (It is a Mechanical Property as Well)

The density of the wood (measured in mass per unit volume) is the backbone of its physical nature. Its hardness and strength depend upon it.

Parameters Affecting Density

- Genetics: genetics define a tree’s innate density.

- Soil, climate, and care play pivotal roles in shaping up.

Values Range

- Trees from higher altitudes, facing harsher conditions and slower growth rates, often yield denser wood [1]. Approximately 70% of trees from elevated locations show enhanced density.

- Softwood average density 350-500 kg/m³, while hardwoods vary greatly, from lightweight balsa to the dense ebony, ranging 500-1200 kg/m³.

You will have common woods’ average densities listed below.

| Wood Type | Density (kg/m³) | Density (lb/ft³) | Type |

|---|---|---|---|

| Pine, radiata | 480 | 30 | Softwood |

| Pine, Scots | 510 | 32 | Softwood |

| Pine, white | 350 – 500 | 22 – 31 | Softwood |

| Pine, yellow | 420 | 26 | Softwood |

| Redwood, American | 450 | 28 | Softwood |

| Redwood, European | 510 | 32 | Softwood |

| Walnut, Amer Black | 630 | 39 | Hardwood |

| Walnut, European | 570 | 36 | Hardwood |

| Teak, Indian | 660 – 980 | 41 – 61 | Hardwood |

| Teak, African | 980 | 61 | Hardwood |

| Teak, Burma | 740 | 46 | Hardwood |

| Oak, American Red | 721 | 45 | Hardwood |

| Oak, American White | 753 | 47 | Hardwood |

| Maple | 625 – 753 | 39 – 47 | Hardwood |

| Cedar, western red | 368 | 23 | Softwood |

| Birch, European | 673 | 42 | Hardwood |

| Ash, white | 641 – 849 | 40 – 53 | Hardwood |

| Alder | 416 – 673 | 26 – 42 | Hardwood |

| Bamboo | 500- 800 | 31 – 53 | Grass |

| Douglas Fir | 530 | 33 | Softwood |

A video on wood properties will be enjoyable for you. You can play it here as well.

Specific Gravity

Specific gravity (SG) of wood is the ratio of the density of the wood to the density of water at 4°C (where water’s density is 1 g/cm³). Directly correlates with wood’s strength. Typical values are like:

- Balsa: Very low SG, around 0.1 – 0.2, which is why it’s extremely lightweight.

- Oak: Typically has an SG of about 0.6 – 0.75 when oven-dried.

Variability

- SG varies among and within wood species.

- Changes are based on the moisture content of the wood.

Influencing Factors

- Growth conditions, age, and part of the tree (heartwood vs. sapwood) can influence SG.

- Drier wood has a higher specific gravity than when it’s more saturated with water.

Applications

- Helps determine if the wood is suitable for specific jobs, like construction or boat building.

- Woods with high SG are generally more durable and resistant to pests.

Moisture Content

The relationship between the cellulose fibers and moisture is intricate and profound.

- Green Wood: Freshly cut, moisture content ranges from 30% to over 200%.

- Air-Dried Wood: Equilibrium with outdoor humidity, usually 12% to 20% moisture content.

- Kiln-Dried Wood: For indoor use, moisture content is reduced to 6% to 10%.

- Equilibrium Moisture Content (EMC): In indoor environments, typically between 8% and 14%.

After the lumber is cut, it will continue to exchange moisture with the surrounding environment until it reaches equilibrium moisture content (EMC), which is a balance point where the wood no longer gains or loses moisture.

During my early years as a wood enthusiast, I remember crafting a cabinet during the rainy season. The resultant warping taught me the pivotal role of moisture in woodworking and pyrography. And, it is a must to make sure the piece is dry and sap-free prior you start burn works on it.

Thermal Resistance and Electrical Conductivity

Its natural insulating abilities are a boon, whether we’re considering thermal insulation or electrical conductivity/resistance.

Thermal Insulation

Thanks to the porosity and minuscule air pockets inside a dry wood. A testament to this material’s brilliance is that its insulation is generally higher than concrete, and of course, much higher than steel of same thickness. The thermal resistance (R-value) per inch of thickness for wood ranges between 1.41 per for most softwoods and 0.71 for most hardwoods. It is between 0.1 and 0.2 for concrete and 0.003 for carbon steel, all values are per inch of thickness.

Electrical Conductivity

Green wood or wood with sap can act as a conductor of electricity to some extent. This is because the moisture content and sap in green wood contain ions and water, which can conduct electricity. While still a relatively poor conductor compared to metals, green wood’s conductivity is notably higher than that of dry wood due to the presence of these conductive elements. [3].

Porosity or the Porous Nature

Pores, Vessels, and Cellular Structure define the wood texture and that vary across species and influence properties like strength, permeability, and appearance [6].

A hands-on experiment I once conducted involved submerging different sampled planks in colored water. The extent and pattern of color absorption visually illustrated corresponding and varied porosity.

Grain Structure

Grain of wood, the alignment and pattern of the grain can reveal growth rates, environmental stresses faced by the tree, and even traumas it may have endured.

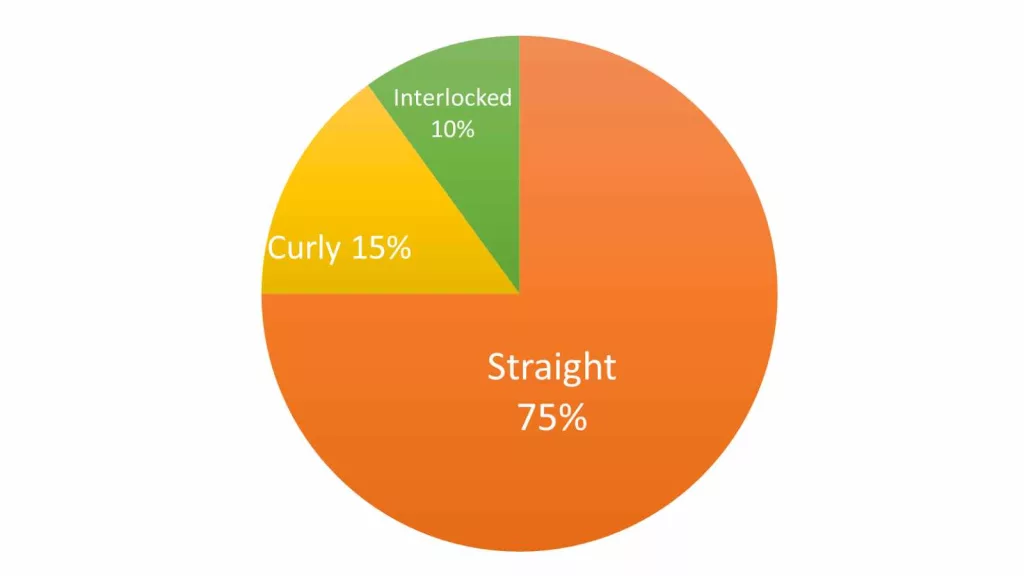

This granular structure impacts both the appearance and workability of the material. A survey conducted by the International Tropical Timber Organization provided the following insights:

- Straight Grain: Approximately 75% of hardwoods sampled had straight grains, denoting uniform and parallel cell alignment.

- Wavy or Curly Grain: Around 15% exhibited wavy or curly grains, often sought after for high-end woodwork due to their distinct aesthetics.

- Interlocked Grain: The remaining 10% showed interlocked grains, where fibers twist around each other, often resulting in challenging workability but offering unique visual appeal. Grain structure impacts its strength, stability, and the manner in which any given wood accepts finishes.

Grain and Texture offers insights into a tree’s life story, from annual growth rings to signs of drought or disease.

Color and Appearance

Color Variations Across Species is vast, with factors such as age, minerals in the soil, and sunlight playing a part.

Parameters Behind the Colors

- Natural Factors:

- Age: Freshly cut timber may have a vibrant hue that deepens or changes over time. For instance, cherry wood darkens as it ages.

- Minerals & Soil: The soil where the tree grows can impact its color due to the minerals it absorbs.

- Environmental Conditions: Sunlight, temperature, and moisture can affect the the color. Prolonged exposure to sunlight might cause certain woods to fade or darken. It depends upon the species and the genetics.

- Human Intervention:

- Staining & Finishing: Stains can change the color to achieve desired aesthetics. A light pine can be stained dark to resemble mahogany, or oak can be lightened for a more contemporary look.

- Treatment: If it is treated for outdoor use, it may have a greenish tint due to preservatives.

Common Colors: A Tabular Overview

| Wood Type | Color Description |

|---|---|

| Pine | Light yellowish-brown |

| Oak | Light tan to dark brown (variations include reddish tones for Red Oak and grayish for White Oak) |

| Walnut | Deep brown with purplish casts and darker streaks |

| Mahogany | Reddish-brown, darkening over time |

| Cherry | Light pinkish-brown, darkening to medium reddish-brown with age |

| Maple | Creamy white to light reddish-brown |

| Teak | Golden to mid-brown, occasionally with darker streaks |

| Cedar | Reddish to pinkish-brown with knots |

| Rosewood | Rich dark brown with black streaks |

| Ebony | Jet black or black-brown |

See the dark reddish gloss of a mahogany wood surface. Beautiful! Isn’t it?

A few years ago, I embarked on a project to restore a vintage wooden table I had stumbled upon at a local flea market. Its golden pine hue, masked by years of neglect, was barely recognizable. However, as I began to sand down the layers, the wood’s original color started to emerge. It was an awe-inspiring transition.

By the end, after a bit of polishing and finishing, the table glowed with a vibrant golden-brown shade, a testament to the beauty of aged pine.

Odor: Chemical Underpinnings and Identification

Every woodworker cherishes the scent of freshly cut timber, most of them are aware of this physical property of timber. But it’s not just about woodworking; understanding the chemistry behind these scents also impacts the realms of perfumery and aromatherapy [5].

| Wood Type | Odor Description | Chemical(s) Responsible |

|---|---|---|

| Pine | Resinous, fresh | Pinene (found in pine resin) |

| Cedar | Sweet, mothball-like | Cedrol, thujaplicin |

| Sandalwood | Warm, rich, woody, and sweet | (Z)-α-Santalol |

| Mahogany | Subtle, not particularly aromatic | Minimal specific volatiles |

| Cherry | Mild, fruity | Benzaldehyde (almond-like aroma) |

| Rosewood | Sweet, floral, with a hint of rose | Linalool |

| Oak | Mild, tannic | Tannins |

| Teak | Leather-like, slightly smoky | Tectoquinone |

| Eucalyptus | Pungent, camphor-like | Cineole |

| Walnut | Mild, nutty | Juglone (in some varieties) |

During a woodworking workshop I attended a few years ago, we were handed blindfolds for an interesting challenge. Each participant was given different wood shavings, and the task was to identify the type based purely on scent. I vividly remember the robust resinous aroma of pine, the distinct sweet scent of cedar, and the pleasantly subtle fragrance of cherry.

Furthermore, in aromatherapy, the calming scents like those of sandalwood and cedar is believed to have therapeutic properties, offering relaxation and mental clarity.

Taste

Taste is considered a physical parameter or property.

- Significance:

- Taste isn’t typically a primary concern in most woodworking applications.

- It becomes crucial in items like utensils, chopsticks, or barrels used for aging beverages.

- Chemical Influence:

- The taste of wood is largely influenced by its chemical composition, including natural oils, tannins, and resins.

- Examples:

- Oak: Used in wine and whiskey barrels, it imparts a distinct flavor to the beverages due to its tannin content.

- Cherry: Often used for smoking meats because of its slightly sweet, fruity flavor profile.

- Toxicity Concerns:

- Some woods can be toxic or cause allergic reactions when ingested.

- Always ensure a wood type is safe for culinary applications before use.

- Alteration:

- The taste of wood can be altered based on treatments, finishes, or the age of the wood.

Acoustic Properties

Musicians and luthiers have long recognized wood’s unique acoustic properties. Choosing Wood for Musical Instruments is an art, with every choice influencing tonality and resonance.

This physical property (acoustics) is very interesting and can be discussed in a few aspects.

- Speed of Sound:

- Spruce, a favorite for soundboards, has a speed of sound of 4,510 m/s.

- Mahogany, used for drums, has a lower speed at 3,970 m/s.

- In wood, this can vary greatly, but typical values for softwoods are in the range of 3300 to 3600 m/s and for hardwoods are 3600 to 4900 m/s.

- Density:

- Density directly impacts sound transmission.

- Denser woods like oak or maple generally produce a brighter tone with a longer sustain.

- Impedance:

- Refers to how a material resists or impedes the flow of sound energy.

- Higher impedance materials reflect more sound energy, while lower impedance materials absorb more.

- Resonance Frequency:

- Every material has a natural frequency at which it vibrates, known as its resonance.

- Woods like spruce or cedar have a broad resonance range, making them popular choices for soundboards in acoustic guitars.

- Damping Factor:

- Damping refers to the reduction of resonance in a material.

- High damping woods, like mahogany, are used for guitar necks to avoid unwanted resonances.

- Internal Friction:

- This measures how sound waves are absorbed within the material, impacting the material’s tonal quality.

- High internal friction woods can produce a warm sound, while low friction might lead to brighter tones.

- Hardness & Stiffness:

- Harder woods tend to produce sharper, clearer tones.

- Softer woods usually yield warmer, more mellow sounds.

- Applications:

- Spruce: Common for guitar tops due to its stiffness-to-weight ratio, allowing for good resonance.

- Rosewood: Often used for backs and sides of instruments because of its wide range of tonal colors.

- Maple: Used in violin, viola, and cello tops. Produces a clear, well-defined tone.

Dimensional Stability

We’ve all experienced a wooden drawer that’s tough to open during monsoons. Wood’s Reaction to Environmental Changes is a testament to its dynamic nature. Warping, Cracking involve understanding wood’s dimensional stability.

Luster

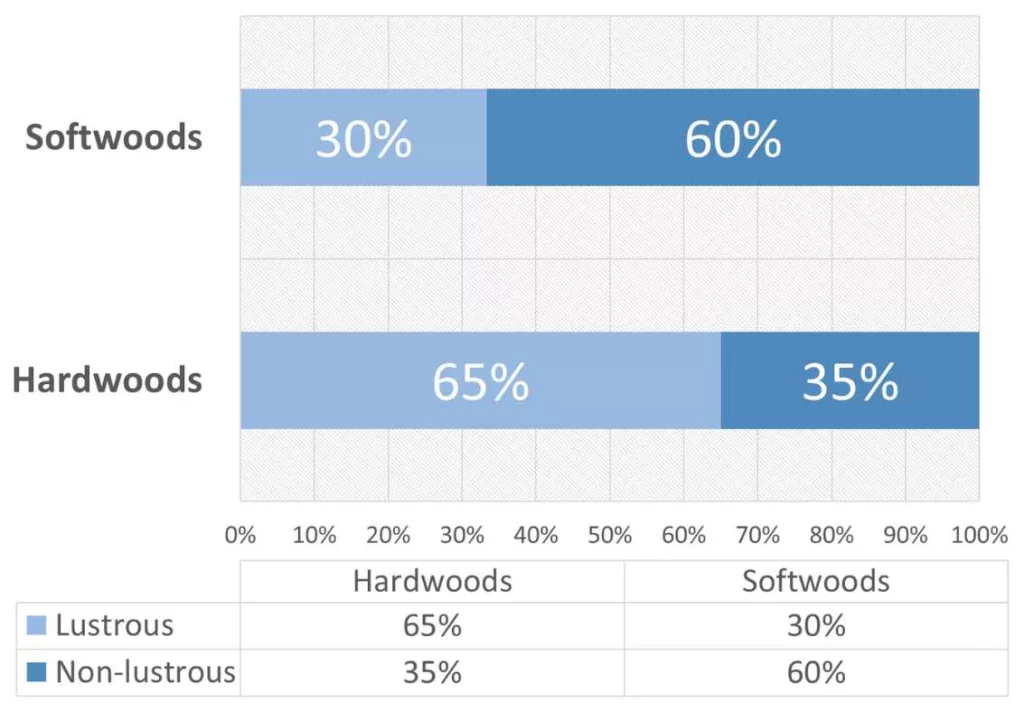

While typically not as shiny as metals, the shininess can range from dull to semi-glossy, depending on the species and the finish applied. Hardwoods like mahogany or cherry tend to have a more pronounced sheen compared to some softwoods. According to a study conducted by the Wood Research Institute:

- About 65% of hardwoods exhibit a medium to high natural soft gloss.

- Only around 30% of softwoods show comparable luster levels.

- The application of finishes, such as varnishes and polishes, can enhance or modify the inherent gloss. An oiled finish might increase it by approximately 40%, while certain matte finishes might decrease it by up to 50%.

Understanding this property is vital not just for aesthetic considerations but also for applications where light reflection might be a concern, such as in interior designing or photography studios.

Age-Rings

Growth ring, often termed as age-ring, is an important physical attribute. It provides chronological snapshots of a tree’s life and the surrounding climatic conditions.

- Each ring typically represents one year of growth.

- Comprised of two segments: earlywood (spring growth) and latewood (late season growth).

- According to a dendrochronological study published in the Journal of Wood Science and Forestry [5], trees in temperate zones have about 60% earlywood and 40% latewood in each ring.

- Drought conditions can result in a 15% reduction in ring width.

- A study of trees from the Northern Hemisphere showed.

- Median of 120 growth rings per tree.

- Some ancient trees had over 500 rings.

On a trip to a protected forest reserve, I had the privilege of observing a cross-section of a centuries-old oak tree. The intricate pattern of its age rings was mesmerizing, and with the help of a local dendrologist, we could trace back notable years of drought and heavy rainfall. This direct interaction with nature’s chronicle was a poignant reminder of the stories trees can tell and the legacy they leave behind.

Shrinkage

Wood’s interaction with moisture is a dance of expansion and contraction, commonly termed as shrinkage and swelling is a major physical property. This behavior stems from the wood’s cellular structure, where cells tend to release or absorb water, leading to dimensional changes. The shrinkage rate, however, can vary widely among different species of wood. According to a comprehensive study by the Wood Science and Forestry Institute:

- Tangential Shrinkage: On average, hardwoods tend to shrink by about 6% – 10% tangentially (parallel to the growth rings) when dried from green condition to oven-dry.

- Radial Shrinkage: The radial shrinkage (perpendicular to the growth rings) for the same species averages between 3% – 5%.

- Longitudinal Shrinkage: Longitudinal shrinkage refers to the reduction in the length of wood fibers along the grain as the wood dries. Longitudinal shrinkage is often very small, typically in the range of 0.1% to 0.2% for many species of wood.

Further Exploration

For enthusiasts seeking a deeper dive:

- “The Woodworker’s Bible” by Percy Blandford, ISBN-13 : 978-1558708266

- “Wood: Identification & Use” by Terry Porter, ISBN-13 : 978-1861084361

- Journals like “Forestry Chronicles“; “Wood Science and Technology” by Springer; 1st ed. 2023 edition (May 5, 2023) ISBN-13 : 978-3030813147

Conclusion

Understanding the intricate ballet of wood’s physical properties is more than academic; it’s about respecting this timeless resource. Sustainable practices, from responsible logging to efficient utilization, ensure that the dance continues for generations.

References

- M. Lewin, et al, Wood Structure and Composition, ISBN 082478233X

- United States Department of Agriculture, Wood Handbook – Wood as an Engineering Material, ISBN-13. 978-0898750829

- G. I. Torgovnikov, Dielectric Properties of Wood and Wood-Based Materials, e-ISBN-13 :978-3-642-77453-9

- Pierre Home Douglas, John Arno, et al., The Art of Woodworking Encyclopedia of wood-Time-Life Books (1993), ISBN-13 : 978-0809499168

- International Journal of Wood Science, Technology and Forestry (IJWSTF). ISSN 1725-3497

- L. F. Botannini, Wood: Types, Properties, and Uses, ISBN-13 : 978-1616688370

FAQs

What are the physical attributes of wood?

These include density, specific gravity, thermal conductivity, hardness, color, shrinkage, age-rings etc.

How does the moisture content affect any wood?

The moisture content affects its density, shrinkage, conductivity, and hardness. As the material absorbs or loses moisture, it can undergo dimensional changes and shrinkage.

What is the density of wood?

It refers to its mass per unit volume and varies depending on the species of tree.

What is the fiber saturation point of wood?

The fiber saturation point is the moisture content at which wood is considered to be fully saturated, but without any free water in its cell walls.

Is wood a good conductor of heat?

Wood is a poor conductor of heat. It has low thermal conductivity, which makes it a good insulator. But while moist, they are very good conductors.

How does the moisture content affect the conductivity of wood?

The moisture content of wood affects its volume, density, and mechanical and electrical properties. As it absorbs moisture, it shows more conductivity and vice-versa. Dry wood is a better insulator than wet ones.

What is the value of wood in construction?

It is valued in construction for its strength properties, aesthetic appeal, and as a renewable building material.